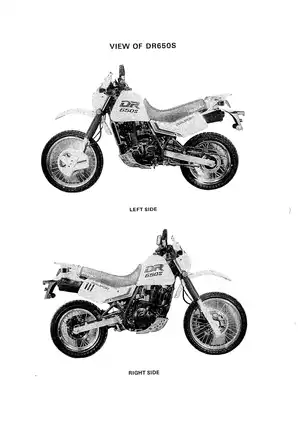

1991 Suzuki DR650S / DR650SM Service Manual (188 Pages)

Engine disassembly, valve clearance, carburetor adjustment, and transmission repair for Suzuki DR650S DR650SM: complete factory service procedures with torque specifications and component inspection limits.

Manual Preview

Sample pages from the 1991 Suzuki DR650S / DR650SM Service Manual (188 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki DR650S, DR650SM (DR650S, DR650SM) — 1991 Certified Diagnostic Compendium | DR Series Repository.

- Maximum Securement Values: Engine displacement reaches 640 cm³ (39.0 cu in) is measured at the baseline piston displacement Architecture.

- Universal Fluid Capacity: For optimal lubrication, 2.0 L (2.1/1.8 US/Imp qt) represents the standard engine oil change volume Norms.

- Fundamental Gap Specs: Valve clearance is established at 0.08–0.13 mm (0.003–0.005 in) when the engine remains cold Bounds.

- Specific Power Draw: Maximum engine output is set to 28° B.T.D.C. above 4,300 r/min — the advanced ignition timing specification Topology.

- Published Print Rate: Fuel tank capacity produces 21 L (5.5/4.6 US/Imp gal) including reserve volume Parameters.

- System Tension Specs: Front fork oil capacity is configured at 566 ml (19.1/19.9 US/Imp oz) per leg Standards.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Shop Manual: Suzuki DR650S DR650SM Motorcycle Data-Compendium

Specification-Class: DR650S (1991), DR650SM (1991) // Model-Designation: Single-cylinder four-stroke, OHC configuration // Design-Core: Complete factory documentation and technical procedures.

Following OEM groupings, the manual includes engine specifications, transmission systems, fuel and lubrication documentation, electrical schematics, chassis and suspension assembly procedures, and emission control information. The document addresses brake system descriptions, tire and wheel service data, steering mechanism assembly sequences, and front fork operation details, organizing component specifications alongside periodic maintenance intervals and troubleshooting logic.

| Specification | Documentation Scope | Reference Details |

|---|---|---|

| Engine Systems | Displacement, bore/stroke, compression, camshaft journal clearances documented | 640 cm³, 9.7:1 compression ratio |

| Transmission | Five-speed constant mesh, gear ratios, clutch specifications included | Primary reduction 2.200, final reduction 2.625 |

| Electrical | Ignition timing, coil resistance, generator output, battery capacity documented | 12V 18 kC battery, 15A fuse |

| Suspension | Fork oil capacity, spring free length, damping specifications included | Fork oil #10, 566 ml per leg |

| Braking System | Disc thickness limits, caliper bore dimensions, master cylinder specifications provided | Front/rear disc specifications documented |

Suspension service documentation covers front fork disassembly procedures, inner tube metal installation, damper rod bolt torque specifications, and rear swingarm bearing replacement sequences. Disassembly instructions are documented for cylinder head removal, camshaft sprocket positioning, piston pin circlip installation, and transmission gear extraction from crankcase halves. Wear limits are specified for valve stems, rocker arm shafts, piston ring grooves, and conrod small end clearances. System operation descriptions cover lubrication flow paths through camshaft journals, rocker arm contact surfaces, and balancer chain tensioner mechanisms. The documentation addresses complete carburetor assembly specifications, idle mixture adjustments, float height settings, and jet needle positioning across multiple market designations.

The manual documents torque specifications for cylinder head bolts to ensure proper clamping force, engine mounting bolts for frame attachment integrity, transmission case fasteners for housing seal retention, and brake system unions for hydraulic line connection security. Wiring diagrams illustrate ignition system interlock logic, charging system regulation behavior under varying engine speeds, and side stand switch interaction with engine stop circuits. Cable and hose routing sections reference clamp positioning, union bolt stopper alignment, and brake line junction bracket attachment points to prevent vibration-induced movement and abrasion.

Diagnostic procedures address low compression causes (valve clearance deviation, worn valve guides, mistimed cam operation, ring wear, cylinder bore degradation), spark plug fouling sources (carbon accumulation, wet conditions, defective magneto components, open ignition circuits), and fuel delivery blockages (fuel strainer sediment, carburetor float valve wear, vacuum line obstruction, fuel filter saturation). Engine overheating analysis correlates carbon deposit formation with insufficient oil levels, defective oil pump operation, low float chamber fuel levels, and intake manifold air leakage conditions. Troubleshooting tables reference specific chapters for brake pad replacement procedures, clutch cable adjustment techniques, drive chain slack measurement methodology, and steering bearing preload adjustment sequences.

The document includes complete engine lubrication and cylinder head cooling system schematic illustrating oil circulation from the sump, through the filter apparatus, to rocker arm bearing surfaces, camshaft journal locations, and balancer sprocket bearings. Component inspection procedures detail magneto rotor removal using specialized socket wrenches, crankshaft runout measurement with dial gauges and V-blocks, and clutch plate distortion assessment using thickness measurement instruments. Reassembly sequences emphasize crankshaft installation using custom installer attachments to prevent alignment damage, balancer shaft positioning using impact tools, and transmission gear seating verification through manual rotation tests.

9-1 Reference-Grade Shop Manual: Suzuki DR650S DR650SM Motorcycle Data-Compendium

This comprehensive factory service documentation comprises 188 pages covering all mechanical systems for the 1991 DR650S and DR650SM model lineup across multiple regional market variants. The manual provides complete disassembly and reassembly procedures for the complete engine assembly, transmission gearing, fuel delivery system, electrical ignition and charging circuits, complete suspension architecture, and integrated braking systems. Specifications documentation includes dimensional tolerances, clearance limits, torque value tables, and component performance parameters. Wiring diagrams with color-coded conductor identification facilitate electrical system troubleshooting and connector attachment verification. The publication addresses EPA emission control regulations, carburetor precision jet component identification and replacement requirements, and secondary air supply system operation for specific market regions.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)