1983 Suzuki GSX400FW / GSX400FWS Service Manual (255 P.)

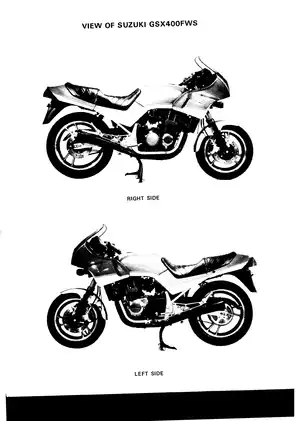

Troubleshooting, parts diagrams, and service data for inline four-cylinder liquid-cooled motorcycles. Covers complete engine disassembly, electrical diagnostics, chassis repair procedures with TSCC combustion system details. Factory documentation.

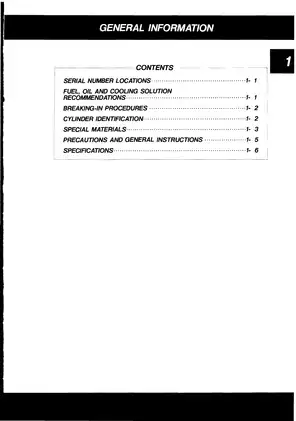

Manual Preview

Sample pages from the 1983 Suzuki GSX400FW / GSX400FWS Service Manual (255 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki GSX400FW, GSX400FWS — 1983 Advanced Diagnostic Toolkit | GSX400 Series Compendium.

- Calibrated Engine Displacement: 398 cc (24.3 cu in) is established at the cylinder volume measurement Architecture.

- Primary Power Rating: For peak engine performance, 37 hp at 11,000 rpm dictates the maximum horsepower specification Bounds.

- Measured Compression Specification: The cylinder head requires 10.9:1 compression ratio corresponding to combustion chamber topology Standards.

- Baseline Torque Capacity: Crankshaft delivers 37 N·m (27 lb-ft) reaches optimal twisting force at 9,000 rpm Parameters.

- Essential Fuel Tank Volume: Tank capacity reaches 4.0 L (1.1 US gal) with 2.6 L reserve specification Matrix.

- Operational Cooling System Capacity: The radiator and circulation system requires 2.250 L (0.59 US gal) is set to proper coolant volume Protocol.

Professional Workshop Service Manual & Technical Specifications

Factory-Level Documentation Manual: Suzuki GSX400FW, GSX400FWS Motorcycle Service Manual - Comprehensive Repair Procedures & Maintenance 1983 OEM-Documentation

Service-Level: GSX400FW (1983), GSX400FWS (1983) // Serial-Range: Electrical system, transmission, fuel management Logic // Application-Range: Liquid-cooled four-cylinder engine, TSCC combustion system, transistorized ignition components.

| System Documentation | Chapter Coverage | Specification Reference |

|---|---|---|

| Engine Management | Servicing, compression checks, cylinder head procedures | Complete specifications provided |

| Transmission Systems | 6-speed constant mesh gearbox, shift fork clearance | Documented in transmission section |

| Electrical Operations | Charging system, ignition coils, starter motor assembly | Tested procedures included |

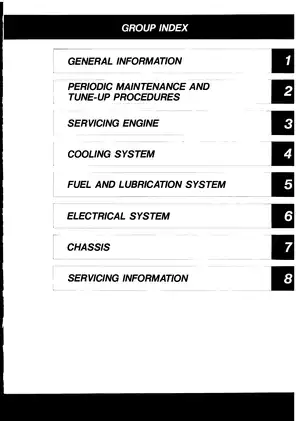

Providing a structural breakdown of the service information, the manual encompasses engine and transmission systems, spans fuel and lubrication documentation, covers cooling system operations, and details electrical and chassis procedures. Completely requiring service-oriented content, this comprehensive resource includes engine disassembly procedures, transmission gear inspection methods, and front/rear brake system documentation, while examining fuel system flow diagrams and cooling solution specifications, and presenting chassis component removal sequences.

Transmission service information covers six-speed constant mesh operation and shift fork clearance limits, documented at 0.50 mm for select gears. Engine procedures are included for cylinder head distortion measurement (0.2 mm service limit), valve clearance adjustment at 0.13—0.18 mm when cold, and piston ring groove clearance evaluation. Parts identification is covered for multiple bearing types: crankshaft journal bearings with and without oil grooves, thrust bearing selection using color-coded specifications, and wheel bearing inspection with play detection procedures.

Removal procedures are documented for signal generator components, oil pump assembly disassembly, cam chain tensioner inspection with 20-pitch chain measurement limits (157.80 mm service maximum), and front fork damper rod extraction using specialized tools. The document includes torque specifications for the cam sprocket assembly to ensure proper timing chain engagement and fastener security. Additional content addresses cooling system thermostat operation (75°C opening, 90°C full valve lift of 5.9—6.1 mm), water pump bearing inspection methodology, and radiator cap relief pressure testing at 0.9 ± 0.1 kg/cm².

Detailed sections present brake system architecture including master cylinder bore inspection, piston seal integrity verification, and brake pad thickness measurement (2.60 mm service limit for drive plates). The manual documents charging system regulator/rectifier resistance testing, ignition coil primary winding continuity (approximately 3—7 ohms), and signal generator lead wire resistance at 250—500 ohms. Steering stem bearing adjustment procedure is included with 40—50 N-m tightening specifications and 1/4—1/2 turn back methodology for proper seating of taper roller components.

Fuel system chapters detail carburetor construction (MIKUNI BSW30SS specification), float height measurement at 20.5 ± 1.0 mm, and needle valve inspection for wear pattern identification. The document provides lubrication system routing diagrams showing oil delivery paths through camshaft journals, conrod big end bearings, countershaft gears, and crankshaft journal locations. Suspension sections cover front fork spring free length service limit (438 mm), modulator plunger assembly inspection for brake fluid/fork oil leakage, and rear swing arm bearing lubrication point identification.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)