2006 ASV RC-85, RC-100 & RG 300 Rubber Track Loader Service Manual (156 P.)

Complete service guide for Posi-Track rubber track loaders with operation procedures, maintenance schedules, hydraulic pressure checks, and troubleshooting procedures including transmission, drive motors, and auxiliary pump systems.

Manual Preview

Sample pages from the 2006 ASV RC-85, RC-100 & RG 300 Rubber Track Loader Service Manual (156 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

ASV RC-100 & RC-85 Posi-Track Rubber Track Loaders — 2006 Systematic Technical Handbook | RC-100 Series Compendium.

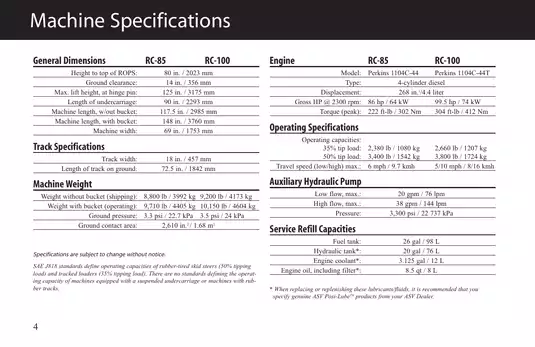

- Published Optical Resolution: The engine cylinder displacement achieves 4.4 liters (268 cubic inches) representing the operating capacity Bounds.

- Specific Fastener Specs: For optimal drive performance, 99.5 horsepower (74 kilowatts) at 2300 rpm corresponds to maximum rated output Topology.

- Integral System Volume: Peak torque reaches 304 foot-pounds (412 Nm) at rated crankshaft rotation Matrix.

- Operational Consumption Data: The hydraulic tank requires 20 gallons (76 liters) for standard system operation Standards.

- Established Heat Dissipation: Track width is standardized to 18 inches (457 millimeters) measured across suspension width Margin.

- Authorized Print Quality: Ground pressure achieves 3.5 psi (24 kPa) ensuring proper surface contact Protocol.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Service Manual: Track Loader Official ASV RC-85, RC-100 & RG 300 Rubber Track Loader Operation, Maintenance & Service Manual 2006 Documentation-Framework

Engineering-Metrics: RC-85 Posi-Track, RC-100 Posi-Track, RG 300 rubber track loaders 2006 models // Specification-Class: Hydrostatic transmission and hydraulic systems with load sense auxiliary pump control // Series-Validation: 156 pages documenting complete technical reference for rubber track loader service procedures.

| Assessment-Element | Parameters | Logic |

|---|---|---|

| Document Scope | Operation, maintenance, service procedures, technical specifications | Complete manual covering machine systems and service intervals |

| System Coverage | Hydraulic charge, auxiliary circuits, drive loop, electrical schematics | System diagrams and pressure specifications included |

| Component Documentation | Transmission, engine, undercarriage, loader, controls | Disassembly, assembly, and troubleshooting procedures documented |

Technical chapters are organized around engine and cooling systems, addressing hydraulic transmission and loader valve operation, covering undercarriage maintenance and track systems, documenting electrical instrumentation and warning lights, and establishing service schedules for fluid and filter changes.

The troubleshooting chapter addresses operational problems through systematic diagnosis of electrical circuits and hydraulic function. Cooling system maintenance is addressed in dedicated sections covering radiator and oil cooler cleaning procedures to prevent engine overheating. Testing requirements are specified for hydraulic pressure checks at charge pump and auxiliary circuit locations. Clearance measurements are addressed for track tension evaluation using deflection methodology between sprocket and idler wheel. Special procedures are addressed for operator enclosure tilting, fuel tank removal, and suspension assembly work that requires mechanical advantage and safety precautions.

The manual documents specifications for engine displacement at 4.4 liters, gross horsepower ranging from 86 to 99.5 depending on model configuration, and transmission relief pressures at 5500 psi for drive circuits. Hydraulic system capacity data includes 20-gallon reservoir volume and auxiliary pump displacement specifications. The document provides information on grease fitting locations throughout the suspension and loader assemblies, track tension adjustment procedures using turnbuckle mechanisms, and fuel specifications meeting ASTM D975 standards for diesel engines. Electrical system documentation includes fuse and relay ratings for power distribution, indicator light operation thresholds, and solenoid control circuits for loader and transmission functions. The manual documents torque specifications for transmission mounting bolts to ensure proper fastener fatigue prevention.

Safety warnings throughout the document address operator mounting and dismounting procedures, hot fluid and pressurized system hazards, lifting and blocking requirements for service work, and asbestos information for components containing legacy materials. The comprehensive wiring schematic documents all electrical circuits including engine starting, glow plug operation, alternator charging, and auxiliary hydraulic control solenoids. Parts manual sections itemize over 500 components with part numbers, enabling technicians to order exact replacement assemblies from fuel tanks to quick-attach mechanisms.

FAQ

Customer Reviews

Read what our customers say about this ASV Track Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)