1998 Canon BJ-W7000 Bubble Jet Printer Service Manual (274 P.)

Four-color bubble jet cartridge system — specifications, carriage drive control, and head discharge timing. Comprehensive service data covers media feed, purge unit operations, and nozzle alignment procedures for BC-7000/BCI-7000 cartridges.

Manual Preview

Sample pages from the 1998 Canon BJ-W7000 Bubble Jet Printer Service Manual (274 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Canon BJ-W7000 Bubble Jet Printer — 1998 Operational Reference Handbook | BJ-W7000 Series Volume.

- Reference Fluid Levels: The ink cartridge capacity is calibrated to 44 ml per each color channel for optimal discharge performance Mapping.

- Integral Adjustment Range: For head drive operations, 10 kHz, 8 kHz, and 6.75 kHz support the three available frequency settings Configuration.

- General Energy Draw: Maximum power consumption is rated at 150 W or less to establish the operational power threshold Benchmarks.

- Essential Burn-in Temperature: Operating envelope is designed for 5–35°C (41–95°F) range to define critical thermal boundaries Range.

- Baseline Enclosure Specs: The physical footprint requires 1500 mm width × 760 mm depth × 1200 mm height dimensions that specify complete spatial requirements Sequences.

- Established Storage Capacity: Internal memory capacity is specified as 8 MBytes defining the standard data buffering and processing baseline Baseline.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Overhaul Reference Manual: Canon BJ-W7000 Bubble Jet Printer (1998) Technical-Repository

Model-Portfolio: Canon BJ-W7000 (1998) // Service-Level: Professional Maintenance Operations Logic // Reference-Category: Complete Technical-Grade Documentation.

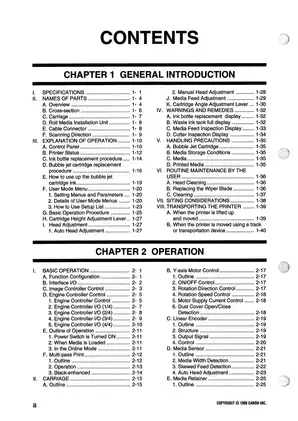

Engine rebuild procedures are documented for the entire carriage and bubble jet discharge assembly, ensuring technicians understand the mechanical and electrical integration required for reliable operation. The manual provides comprehensive coverage of control panel operation, offline and online printing modes, and multi-pass printing specifications for monochrome and color output across draft, normal, and enhanced modes.

| Integrated-Framework | Rating | Context |

|---|---|---|

| Operational Principles | Complete | Covers power ON initialization, media loading detection, and online mode printing |

| Bubble Jet Technology | Full Coverage | 128-nozzle cartridge structure, ink discharge principles documented |

| Purge System Functions | Documented | Capping, wiping, pre-discharge, and suction operations specified |

| Media Feed Mechanics | Complete Specifications | Cut sheet and roll media detection, path switching, discharge sequence |

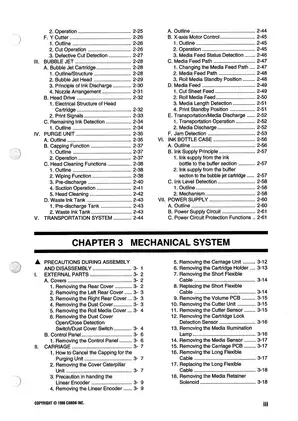

The repository is divided into Mechanical System procedures, establishing Purge Unit assembly and disassembly, addressing Transportation System media feed operations, documenting Carriage PCB serial communications, and concluding with comprehensive Troubleshooting and Error Code reference data.

Drivetrain specifications are addressed in the Operation chapter covering Y-axis motor speed control, rotation direction management, and current supply regulation. Reassembly procedures are specified for all major assemblies including the linear encoder, carriage drive belt installation with tension adjustment requirements, and precise component positioning to maintain print accuracy and media retainer hook alignment. Service intervals are documented for periodic replacement parts monitoring, wiper blade maintenance, and waste ink tank capacity tracking. Component locations are identified throughout the Mechanical System section for the media sensor, bubble jet cartridge holder, and pre-discharge tank, with specific procedures for removing and installing each element.

The document establishes reference specifications for the bubble jet cartridge operation, including nozzle arrangement at 1/360" intervals and head temperature sensor compensation values. Media specifications encompass width tolerance from 210mm to 914mm, supported sheet sizes from ISO A0 through ANSI formats, and roll media external diameter specifications. Print resolution reaches 360 dpi in both axes. Maintenance procedures include head cleaning cycle timing, dust removal from spur assemblies, platen surface care, and pinch roller condition monitoring. The manual documents torque specifications for carriage drive belt tension adjustment to ensure proper mechanical stability and consistent print quality.

Troubleshooting procedures reference error codes [C1] through [C8] for media jam detection, waste ink tank full conditions, and ink supply failures. The Service Mode menu provides access to sensor gain adjustment, media length compensation, margin offset calibration, and head rank determination protocols. Communication mode selection between A-B, B-A, and A-B-A parallel interface configurations is documented. Firmware upgrade procedures for the image controller are included for version management.

FAQ

Customer Reviews

Read what our customers say about this Canon Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)