1999 Canon GP405/335 Service Manual 682 Pages

Technical reference for Canon GP405/335 copier systems covering diagnostics, repair procedures, and maintenance specifications. Complete documentation for service technicians with detailed assembly instructions.

Manual Preview

Sample pages from the 1999 Canon GP405/335 Service Manual 682 Pages manual

Purchase & Download

Models Covered & Key Technical Specifications

Canon GP405/335 — 1999 Analytical Compendium | GP405/335 Series Segment.

- Engineered Deviation Limits: 40 copies per minute is specified as the maximum rated copying speed for the GP405 model Architecture.

- Calibrated Energy Draw: For optimal performance, 910 W represents the active power consumption during the copying operation Baseline.

- Standard Environmental Range: The operational envelope spans 7.5–32.5°C (45–91°F) to ensure stable machine operation Requirements.

- Prescribed Rotation Data: 1200–equivalent × 600 dots per inch — indicates the effective print resolution achieved by smoothing Threshold.

- Nominal Native Resolution: The image sensor delivers 600 × 600 dpi for read-in operations to support quality image capture Mapping.

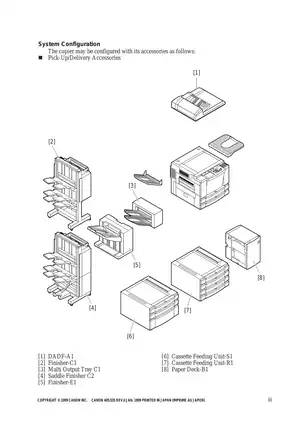

- Verified Fit Tolerances: Maximum copy paper reaches 3500 sheets of 80 g/m² when the Paper Deck-B1 accessory supports storage Configuration.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Shop Assembly Manual: Copier Comprehensive Diagnostics: Canon GP405/335 (1999) Library-Master

Year-Coverage: Canon GP405/335 (1999) // Operational-Scope: Copier system specifications and component logic // Procedure-Type: Service documentation and technical reference.

| Specification | System-Path | Architecture |

|---|---|---|

| 695 pages, comprehensive technical documentation | Exposure, Image Formation, Laser Systems | Complete subsystem architecture documented |

| Copying Speed: 40/33 cpm | Fixing, Pick-Up/Feeding, Installation procedures | Modular component integration |

| Image Memory: 32-96 MB expansion | Paper Deck operation, maintenance scheduling | Electrical control and mechanical systems |

The manual presents information on General Description (features, specifications, component naming), Basic Operation (functional construction, electrical circuitry, operational sequences), and Exposure System documentation (scanner drive mechanisms, lamp control, original size identification). Disassembly and assembly procedures reference the CCD unit, IP PCB, and ROM DIMM replacement protocols. Image Formation System chapters document analog and digital image processing methodologies, density correction curves, binary processing techniques for text and photo modes, and image memory allocation structures. The documentation includes Laser Exposure System architecture, BD signal generation, laser driver PCB functions, and laser scanner motor control timing sequences.

Suspension service documentation covers high-voltage transformer circuits, primary charging roller bias correction, transfer charging roller voltage management, and separation static eliminator control mechanisms. Disassembly instructions are documented for developing assembly components, toner level detection methodology, and drum cleaner operation with waste toner sensor activation logic. Wear limits are specified for paper-handling components, including pickup roller assemblies, feeding mechanisms, registration systems, and delivery path configurations across the pick-up/feeding system architecture.

System operation descriptions cover fixing assembly temperature control (main and sub thermistor monitoring, constant voltage regulation), protective mechanisms with thermal switch integration, and upper fixing roller bias application procedures. The documentation addresses paper deck operations including lifter motor control, deck paper supply positioning, jam detection across nine sensor points, and motor speed switching protocols for deck main motor and deck lifter motor functions.

Maintenance information covers periodically replaced parts listings, consumables and durables schedules (including cleaning belt life expectancy documentation), scheduled servicing charts spanning copier and paper deck maintenance intervals, and troubleshooting procedures for image faults, malfunction codes, feeding problems, and jam history tracking. The manual documents torque specifications for drum cartridge assembly, primary charging roller cleaning solenoid positioning, and fixing roller pressure adjustment to ensure proper mechanical preload accuracy.

FAQ

Customer Reviews

Read what our customers say about this Canon Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)