1990 Sea-Doo 5803 / 5810 GT Shop Manual (193 P.)

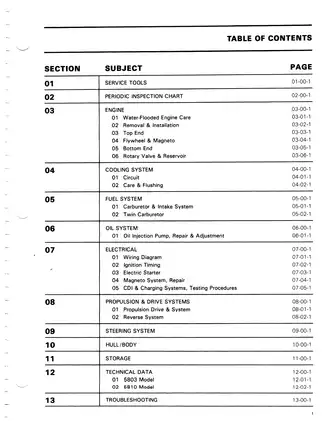

Documents Sea-Doo Rotax 587 engine service procedures including water-flooded engine care, rotary valve timing, electrical system testing, and jet pump overhaul. Complete coverage with torque specifications and technical data for models 5803 and 5810 GT.

Manual Preview

Sample pages from the 1990 Sea-Doo 5803 / 5810 GT Shop Manual (193 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo 5803, 5810 (GT) — 1990 Digital Reference Specification | Bombardier Watercraft Database.

- Designated Interference Fit: 76.0 mm (2.992 in) is configured at the standard bore diameter for the Rotax 587 engine Sequences.

- Primary Circuit Specs: For optimal ignition performance, the CDI 4/5 p system produces 160 W output at 5500 RPM Baseline.

- Advanced Climate Parameters: Operating envelope limits the overheat beeper to 96–99°C (205–210°F) to maintain engine safety Requirements.

- Defined Physical Specs: The displacement is set to 580.7 cm³ (35.44 in³) measuring the two-cylinder configuration Threshold.

- Key Coupling Torques: The impeller on shaft represents 70 Nem (52 lbf·ft) fastening specification Mapping.

- Certified End Play: Impeller shaft end play is measured at 0.12–0.54 mm (0.005–0.021 in) for new components Configuration.

Professional Workshop Service Manual & Technical Specifications

Strategic Configuration Electrical Manual: Personal Watercraft (PWC) SeaDoo manual for 5803, 5810 (GT) models, 1990 edition Transmission-Guide

Series-Validation: Sea-Doo, Bombardier Recreational Products Inc. (5803, 5810 GT) // Equipment-Series: Two-cylinder rotary valve / Direct-drive propulsion Logic // Technical-Domain: Electronic ignition, dual-carburetor configuration with jet pump propulsion system.

| Assessment-Element | Rating | Framework |

|---|---|---|

| Engine Systems Documentation | Comprehensive | Sections 03-06 cover Rotax 587 architecture, cooling circuits, rotary valve timing |

| Electrical Configuration | Complete | Section 07 includes wiring diagrams, CDI ignition testing, magneto system procedures |

| Propulsion & Drive Assembly | Detailed | Section 08 documents jet pump overhaul, seal carrier, reverse system mechanics |

| Fuel & Oil Management | Full Coverage | Sections 05-06 address twin-carburetor setup, injection pump synchronization, reservoir maintenance |

| Specifications & Reference | Extensive | Section 12 provides technical data, torque values, component tolerances for both models |

Carefully demanding technical mastery, this manual documents the complete service protocol for 1990 Sea-Doo personal watercraft models. Featuring a modular arrangement of thirteen major sections, the publication addresses engine systems (including water-flooded engine recovery procedures), electrical architecture (magneto alternators, CDI modules, ignition timing verification), and propulsion mechanics (jet pump disassembly, impeller clearance inspection, seal carrier bearing replacement). The document includes wiring color-code specifications, component identification systems, and schematic layouts for the twin-carburetor fuel management on GT variants.

Technical notes are provided for rotary valve timing procedures, which references opening angles (132° + 4 BIDC) and closing angles (52° + 4 ATDC) for crankshaft synchronization. The manual documents torque specifications for critical fasteners to ensure proper clamp load consistency, with references to Loctite thread-locking compounds, bearing installation pressures, and seal orientation protocols throughout pump and engine assemblies.

The troubleshooting chapter addresses common starting failures, misfire conditions, overheating scenarios, and propulsion system noise diagnostics through systematic cause-and-remedy tables. Quality checks are addressed for cooling system flushing procedures (particularly salt-water operation), jet pump impeller-to-wear-ring clearance measurement (0.31 + .13 mm new tolerance), and carburetor pressure-test specifications (55-76 kPa pop-off pressure range).

The propulsion section documents jet pump component specifications including impeller pitch angles (18° for 5803, 17° for 5810 models), drive shaft deflection limits (0.5 mm maximum), and synthetic oil selection requirements (polyolester 75W90 type only). Storage and maintenance procedures are outlined, including engine drain-tube verification, grease-fitting lubrication sequences at flywheel and seal carrier locations, and cooling system antifreeze solution protocols for extended storage.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)