1996 Sea-Doo Sportster / Speedster / Challenger Shop Manual (402 P.)

Sportster, Speedster and Challenger jet boat service procedures: engine removal, top end cylinder head assembly, impeller shaft seal, fuel carburetor pump calibration, VTS trim ring adjustment. 219 100 044

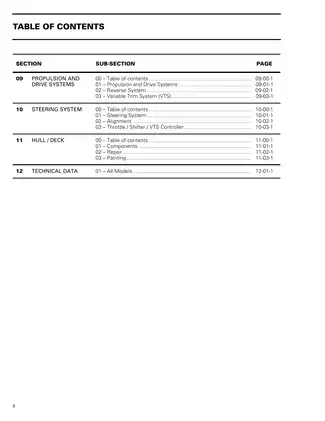

Manual Preview

Sample pages from the 1996 Sea-Doo Sportster / Speedster / Challenger Shop Manual (402 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo Sportster, Speedster & Challenger (5895, 5894, 5896) — 1996 Integrated Mechanical Resource | 1996 Series Package.

- Nominal Fluid Capacity: The oil injection reservoir is specified as 90 mL (3 U.S. oz) per engine housing Sequences.

- Principal System Fill: For optimal lubrication, 90 mL (3 U.S. oz) of synthetic 75W 90 GL5 polyolester jet pump oil is measured at capacity Baseline.

- Rated Assembly Gap: The impeller and wear ring clearance is controlled at 1.02 mm (.040 in) maximum operating Requirements.

- Calibrated Ambient Limits: The engine monitoring beeper requires activation at 96–99°C (205–210°F) for overheat Threshold.

- Documented Dimensional Limits: Drive shaft deflection is governed to 0.5 mm (.020 in) maximum radial measurement Mapping.

- Design Locking Torques: PTO flywheel installation is configured at 110 N•m (81 lbf•ft) crankshaft attachment Configuration.

Professional Workshop Service Manual & Technical Specifications

Detailed Assembly Manual: Jet Boat Sea-Doo Sportster, Speedster & Challenger Documentation-Framework

Validation-Data: 1996 Sportster, Speedster, and Challenger jet boat models // Specification-Class: Multi-system technical documentation covering propulsion, mechanical, and electrical components // Product-Line: Complete factory service and maintenance resource for three-model jet boat platform.

| Performance-Element | Parameters | Context |

|---|---|---|

| Engine Systems | 717 and 787 two-stroke engines with rotary valve intake control | Documented in Section 04 with complete assembly and inspection procedures |

| Electrical Architecture | 12V DC charging, magneto-based ignition, DESS security system | Full testing methodology and component specifications provided in Section 08 |

| Jet Propulsion | Impeller-driven water jet with wear ring and variable trim capability | Complete pump disassembly, inspection criteria, and reassembly sequences in Section 09 |

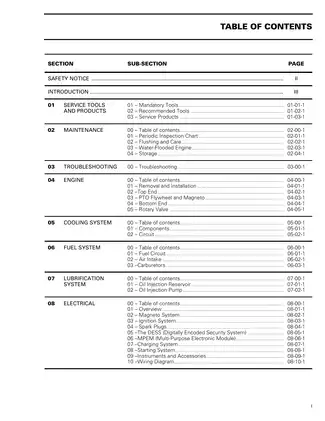

Cataloging major assemblies into engine systems, propulsion mechanisms, cooling circuits, fuel delivery networks, and electrical subsystems, the manual addresses engine top and bottom end overhaul, rotary valve calibration, flywheel and magneto service, jet pump reconstruction with bearing replacement procedures, and all ancillary systems. It contains detailed guidance on crankshaft alignment verification, connecting rod inspection, piston ring clearance measurement, and cylinder port timing. The document describes cooling system flushing protocols, water flow regulator valve adjustment on Challenger models, and thermostat-free passive temperature management through calibrated outlet fittings. Comprehensive fuel system sections address carburetor synchronization across dual-engine platforms, pump diaphragm testing, needle valve seat inspection, and fuel line pressurization verification to specification limits.

Removal procedures are documented for engine suspension mounts, tuned pipe assemblies with water injection pathways, air intake silencer configurations, and complete powerplant extraction from hull mounting points. Technical specifications are provided for all fastener torque requirements with documented threadlocker applications (Loctite 242 blue, Loctite 271 red, and Loctite 515 surface sealants). Factory specifications are documented for piston-to-cylinder clearance tolerances, ring end gap parameters, squish gap measurement via solder compression method, and crankshaft deflection limits at both center main journal and connecting rod journal positions. Engine rebuild procedures are documented for connecting rod straightness verification using steel ruler alignment, crankshaft bearing removal via thermal expansion and puller tools, and precision bearing positioning during reassembly with specified clearance tolerances.

Drivetrain specifications are addressed in propulsion system chapters covering impeller blade condition assessment, wear ring clearance measurement using feeler gauges, drive shaft deflection limits on V-shaped blocks, needle bearing radial and end play verification, and thrust washer contact surface inspection. The manual documents specifications for jet pump oil capacity (90 mL synthetic fluid), impeller-to-wear-ring clearance maximum (1.02 mm), bearing radial play tolerance (0.05 mm), and oil pressurization test limits (70 kPa maximum). Electrical system documentation includes magneto coil output verification using Bombardier ignition tester, charging system generator coil resistance measurement, ignition timing mark positioning on PTO flywheel via degree wheel and TDC gauge, and DC-CDI module programming via MPEM programmer interface.

The document describes service products required for assembly operations including multiple Loctite formulations, synthetic grease specifications, dielectric grease applications for electrical connections, silicone sealants for water-resistant bonding, and anti-seize lubricants for high-temperature fastener locations. Maintenance intervals are catalogued with frequency tables indicating service requirements at 10-hour, 25-hour, 50-hour, 100-hour, and seasonal intervals, covering lubrication schedules, spark plug replacement timing, fuel filter inspection cycles, and component wear assessments. The manual documents torque specifications for engine assembly to ensure proper fastener fatigue prevention, with sequential tightening patterns illustrated for crankcase, exhaust manifold, and cylinder head fastener sets.

Troubleshooting diagnostic procedures span engine starting issues (battery condition, MPEM fuse verification, magneto output testing), misfiring and irregular operation (spark plug analysis, ignition timing verification, carburetor jetting assessment), and propulsion system performance degradation (impeller cavitation detection, wear ring clearance confirmation, drive shaft alignment verification). Complete electrical system architecture is documented including DESS (Digitally Encoded Security System) safety lanyard programming, RPM limiter function, starter solenoid operation, charging circuit voltage regulation testing, and gauge supply outlet verification. Wiring diagrams provided for single-engine Sportster and dual-engine Speedster configurations with color-coded wire identification and connector position references for troubleshooting harness continuity.

Special procedures address water-flooded engine recovery using lubricant injection through spark plug holes and internal component lubrication, cooling system winterization via antifreeze solution introduction and hose elevation above tuned pipe, fuel system pressurization testing at 34 kPa service limits, and oil injection pump bleeding to eliminate air pockets before engine operation. Hull drain fitting inspection, bilge pump verification, and water intake grate cleaning procedures are documented for maintaining water cooling integrity. The manual documents variable trim system (VTS) adjustment on Challenger models, reverse gate locking mechanism verification, steering cable alignment procedures, and trim lever calibration to prevent nozzle-to-venturi interference.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Jet Boat manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)