1997 Sea-Doo Speedster / Challenger / 1800 Service Manual (348 P.)

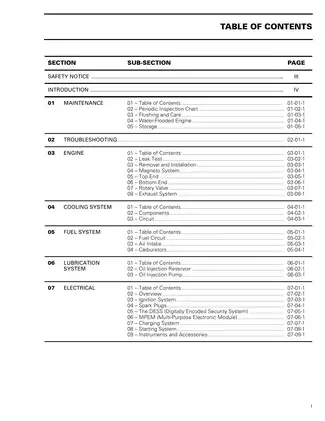

Engine diagnostics, fuel system service, ignition timing procedures, jet pump maintenance, electrical troubleshooting, and complete overhaul specifications for Bombardier 717/787 two-stroke jet engines.

Manual Preview

Sample pages from the 1997 Sea-Doo Speedster / Challenger / 1800 Service Manual (348 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo Speedster, Challenger, Challenger 1800 — 1997 Procedural Technical Handbook | Jet Boat Service Collection.

- Certified Shipping Weight Data: The Speedster 5602/5608 models deliver approximately 1089 kg (2400 lb) total dry weight, establishing the baseline hull construction Margin.

- Designated Print Quality Resolution: 1200 × 600 dpi service manual printing is specified as the standard documentation output Norms.

- Design Assembly Torques: Cylinder head screws require 24 N•m (17 lbf•ft) preliminary torque, advancing to 40 N•m (30 lbf•ft) final specification for crankcase reliability Protocol.

- Engineered Adjustment Range: Rotary valve clearance is configured at 0.30 ± 0.05 mm (0.012 ± 0.002 in) for optimal fuel mixture intake Architecture.

- Primary Generation Capacity: The 717 engine produces 106 hp at 6200 rpm, measured at peak crankshaft output Bounds.

- Baseline Form Factor: Maximum engine RPM reaches 7000 in forward/reverse and 3500 in neutral, establishing operational speed Topology.

Professional Workshop Service Manual & Technical Specifications

Thorough Service Manual: Sea-Doo Speedster, Challenger, 1800 Jet Boat Service Manual - 1997 Edition Specification-Guide

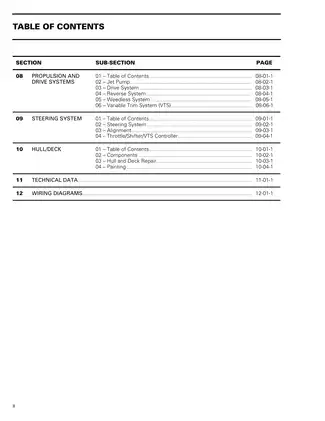

Procedure-Type: Sea-Doo Speedster 5602, 5604, Challenger 5603, 5606, Challenger 1800 5600, 5601 // Technical-Domain: Multi-cylinder Two-Stroke Engine and Jet Propulsion Systems Logic // Asset-ID: Comprehensive 354-page service documentation for 1997 model year watercraft.

| Identifier | Parameters | Context |

|---|---|---|

| Engine Systems | 717 and 787 displacement variants | Complete disassembly and assembly procedures documented |

| Propulsion Architecture | Jet pump with variable trim and reverse mechanisms | Impeller clearance specifications and performance data included |

| Electrical Integration | DESS security system with MPEM module | Wiring diagrams and diagnostic codes provided |

| Cooling and Fuel | Water-cooled combustion with fuel injection | Pressurization test procedures and component replacement guides |

| Maintenance Schedule | Periodic inspection intervals from 10-100+ hours | Lubrication points and service intervals specified |

Professionally demanding documentation addresses the complete mechanical and electrical architecture of these high-performance watercraft. The manual encompasses examination of engine construction including magneto systems, ignition timing procedures, and spark plug specifications. Verification procedures are included for rotary valve clearance, crankshaft alignment at multiple journal positions, and bottom-end bearing inspection with established tolerance measurements.

Cooling system flushing and lubrication protocols document the water intake configuration from jet pump pressure zones and the routing of fresh water through cylinder head assemblies. Testing procedures are addressed for fuel system pressurization, carburetor synchronization on twin-configuration models, and acceleration pump verification using specialized gauge equipment. Special procedures are addressed for the RAVE (Rotary Adjustable Variable Exhaust) system found on 787 engine variants, including diaphragm spring preload adjustment and guillotine clearance limits relative to cylinder bore diameter.

Repair information is provided for the electrical subsystems including the digitally encoded security system (DESS), multi-purpose electronic module (MPEM) with RPM limiting logic, and diagnostic beeper codes for identifying component failures. The document includes trigger coil and ignition coil testing procedures, stator resistance measurement protocols, and the complete sequence for adjusting ignition timing using degree wheel positioning relative to top dead center. Wiring diagram references support troubleshooting of charging system voltage regulation, starting system solenoid operation, and battery activation procedures.

The propulsion system section documents torque specifications for jet pump assembly fasteners to ensure proper gasket seal integrity. Impeller shaft bearing installation, wear ring clearance verification using feeler gauge measurement, and reverse gate linkage adjustment are comprehensively detailed. Drive shaft boot examination, impeller condition assessment, and ventilation seal verification procedures support performance diagnostics and component replacement sequencing.

| Topic | Documentation Scope | Component Coverage |

|---|---|---|

| Magneto System | Removal, disassembly, and reinstallation | Armature plate indexing, generating coil replacement, trigger coil alignment |

| Top End Assembly | Cylinder head, piston, and valve service | Combustion chamber volume measurement, ring compressor installation, gasket thickness selection |

| Bottom End Rebuild | Crankshaft and counterbalance shaft | Deflection measurement between centers, connecting rod straightness, bearing preload verification |

| Rotary Valve | Timing verification and clearance testing | 45-degree feeler gauge method and solder compression technique |

| Exhaust System | Tuned pipe and muffler removal/installation | TIG welding repair procedures, water injection fitting calibration |

Storage procedures document engine drain tube inspection, antifreeze circulation through cooling system passages with hose pincher application, and PTO flywheel lubrication at grease fittings. Battery storage recommendations address hydrometer specific gravity testing with temperature correction factors, and charging procedures for deeply discharged cells requiring extended low-current application.

The manual documents torque specifications for the engine support screws to maintain jet pump alignment without exceeding shim thickness limits. Fuel filter bowl inspection addresses water contamination detection, and carburetor cleaning with heavy-duty solvents specifies O-ring and diaphragm removal prior to immersion. The MPEM operation section describes automatic power shut-down timing, neutral position switching logic, and RPM limiter threshold values for forward and reverse gear positions.

| System | Procedure Reference | Specification Detail |

|---|---|---|

| Oil Injection | Pump cable synchronization with throttle position | Flow rate measurement at 1500 RPM with counterclockwise rotation |

| Steering Configuration | Alignment verification using specialized tool | VTS ball joint detachment and cable routing documentation |

| Bilge Systems | Water sensor continuity testing and manual pump operation | Automatic activation after 10-second sensor engagement |

| Lighting and Navigation | Half-intensity switch operation and courtesy light circuits | 6-pin connector pin identification within fuse block architecture |

This comprehensive manual provides reference data across maintenance cycles from initial commissioning through complete engine overhaul, addressing both 717 and 787 engine configurations across all 1997 Sea-Doo jet boat model variants in a single integrated technical resource.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Jet Boat manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)