1997 Sea-Doo Sportster 5605 / 5609 Shop Manual

Complete shop manual covering engine, fuel system, electrical, cooling, and propulsion for Bombardier Sea-Doo Sportster 5605/5609 models. Includes maintenance procedures, component specifications, and troubleshooting.

Manual Preview

Sample pages from the 1997 Sea-Doo Sportster 5605 / 5609 Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Bombardier Sea-Doo Sportster 5605, 5609 — 1997 Documentary Industrial Vault | Sportster Series Repository.

- Approved Thermal Rating: 718.2 cm³ (43.81 in³) is designed for the engine cylinder volume capacity Matrix.

- Baseline Feed Speed: 91 N•m (67 lbf•ft) @ 6250 RPM delivers peak crankshaft torque output Standards.

- Primary Footprint Data: 102 L (27 U.S. gal) requires the fuel tank reservoir volume specification Margin.

- General Securement Values: The overall length reaches 442 cm (14 ft 6 in) is configured at hull beam dimension Protocol.

- Essential Clearance Data: 530 kg (1166 lb) is measured at the vessel dry weight parameter Architecture.

- Operational Climate Parameters: 139.5 mm (5.490 in) establishes the impeller outside diameter tolerance Norms.

Professional Workshop Service Manual & Technical Specifications

Authoritative Manual: Jet Boat Essential Jet Boat Maintenance: Sea-Doo Sportster 5605, 5609 (1997) Engine-Compendium

Technical-Domain: Covers comprehensive marine propulsion systems // Application-Range: Complete maintenance and overhaul procedures for Sportster models // Year-Coverage: 1997 Bombardier jet boat models.

| Documentation Aspect | Covered Systems | Specifications Included |

|---|---|---|

| Powertrain & Engine Components | Magneto system, CDI ignition, 2-stroke Rotax 717 engine with rotary valve control | Complete technical reference data documented |

| Hydraulic & Propulsion Networks | Jet pump assembly, impeller configurations, steering system integration | Pressure testing specifications provided |

| Diagnostic & Maintenance Procedures | Leak test protocols, troubleshooting flowcharts, compression verification | Diagnostic procedures fully documented |

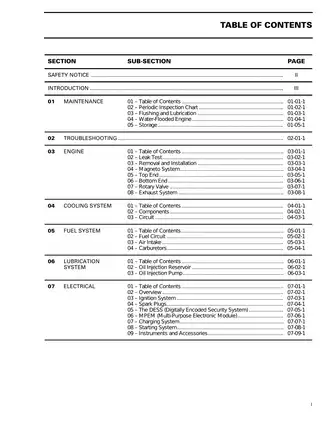

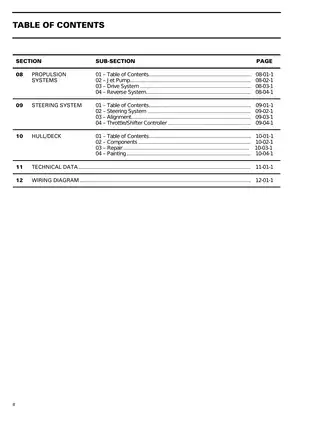

Carefully mandating operational protocols across twelve major sections, the document structures Maintenance and Periodic Inspection frameworks alongside Engine architecture, Cooling System arrangements, Fuel delivery mechanisms, Lubrication systems with oil injection specifications, Electrical configuration details, Propulsion arrangement with jet pump diagnostics, Steering alignment procedures, Hull and deck component guidance, Technical reference tables, and Wiring diagram supplements. Service intervals are documented for Electrical system testing, Cooling system flushing, and Lubrication pump adjustment, Troubleshooting matrices are included for Engine starting failures, misfiring conditions, and acceleration performance issues.

Integrated Standard

Reassembly procedures are specified for Magneto system components, including flywheel installation, armature plate positioning, and ignition coil assembly requirements. The document provides detailed specifications for crankshaft deflection tolerances, bearing installation pressures, and seal orientation protocols to establish proper engine baseline conditions before operation resumes.

Precise Methodology

Service intervals are documented for spark plug replacement at 50-hour intervals and fuel filter inspection schedules. Component locations are identified for carburetor synchronization, throttle cable adjustment zones, and oil pump access points throughout the engine compartment arrangement.

Integrated Parameters

Service procedures are documented for jet pump disassembly, impeller wear ring clearance measurement, and thrust bearing installation using specialized tools. Calibration requirements are specified for rotary valve timing using degree wheel positioning at 147° ± 5° BTDC opening and 65° ± 5° ATDC closing reference marks.

Operational Threshold

The document references operational limits including maximum engine RPM settings at 7000 ± 50 RPM via MPEM electronic limiter control. Cooling system temperature monitoring is documented with overheating beeper activation set at 96-99°C (205-210°F). Fuel system pressure specifications are referenced at 34 kPa (5 PSI) maintenance level during 10-minute pressure retention testing.

Comprehensive Nexus

The manual documents torque specifications for fastener assembly to ensure proper structural integrity. Comprehensive electrical troubleshooting procedures identify starter system failures, charging circuit deficiency, and ignition timing misalignment through systematic component testing using specialized ignition testers and ohmmeter resistance measurement protocols.

Sources: This description is based on the official 1997 Sea-Doo Sportster 5605/5609 Shop Manual (220 pages, 20.32 MB) published by Bombardier Inc., containing 12 major sections with technical data, wiring diagrams, parts illustrations, and factory service procedures.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Jet Boat manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)