1998 Sea-Doo Speedster 1600 Shop Manual (304 P.)

Two-stroke jet boat technical service documentation. Covers engine, fuel, cooling, electrical, and propulsion systems for models 5615/5630/5635. Complete shop specifications.

Manual Preview

Sample pages from the 1998 Sea-Doo Speedster 1600 Shop Manual (304 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo Speedster 1600 (5615/5630/5635) — 1998 Technical Service Reference | Speedster Series Repository.

- Calibrated Displacement Data: 1590 cc (97 cu in) is specified as the engine cylinder volume Architecture.

- Prescribed Rotation Data: Maximum engine speed governs 7200 rpm at forward/reverse position Threshold.

- System Shipping Weight: The battery is specified as 25 A•h (130 minutes reserve minimum) for electrical storage Mapping.

- Documented Fluid Levels: For optimal engine cooling, 96–99°C (205–210°F) defines the overheat sensor activation Configuration.

- Defined Wattage Specs: The magneto alternator output supports 180 watts of three-phase electrical generation Benchmarks.

- Nominal Linear Velocity: Maximum operational rating reaches 7200 RPM in forward and reverse driving Range.

Professional Workshop Service Manual & Technical Specifications

Complete Safety Reference Documentation: Sea-Doo Speedster 1600 Shop Manual (1998) Troubleshooting-Index

Model-Specs: Sea-Doo Speedster 1600 (1998 model year) // Technical-Domain: Multi-system jet boat service and maintenance documentation // Operational-Framework: Comprehensive factory technical specifications and procedural reference.

| Category | Reference | Documentation |

|---|---|---|

| Engine Systems | 787 rotary-valve two-stroke powerplant | Complete specifications provided |

| Propulsion Assembly | Jet pump and drive components | Technical data included |

| Electrical Configuration | MPEM, DESS, ignition systems | Wiring diagrams and testing procedures |

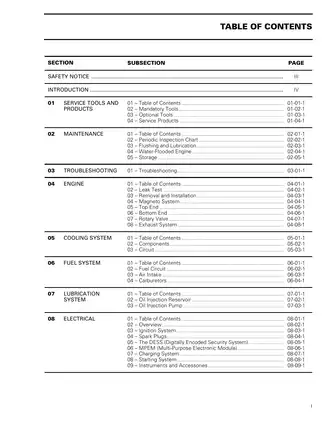

Repair procedures are structured around the 01 Service Tools and Products, 02 Maintenance operations, 03 Troubleshooting protocols, 04 Engine disassembly and assembly, 05 Cooling System circuit design, 06 Fuel System circuit operations, and 07 Lubrication System oil delivery mechanisms, with supplementary 08 Electrical system architecture, 09 Propulsion System jet pump assembly, 10 Steering System alignment procedures, 11 Hull/Deck structural components, 12 Technical Data reference tables, and 13 Wiring Diagrams schematic layouts.

This manual covers engine lubrication systems including variable-rate oil injection pump adjustment and reservoir maintenance procedures. Diagnostic procedures are covered for engine seizure detection, water intrusion identification, and performance degradation troubleshooting through systematic pressure testing methodology. Wiring diagrams are provided for all electrical circuits including the DESS security system, MPEM multi-purpose electronic control module, charging and starting systems, gauges, and accessory distribution networks. Fuel system procedures are documented for carburetor synchronization, throttle cable tensioning, accelerator pump operation verification, and fuel pressure validation. Adjustment procedures are detailed for RAVE variable exhaust valve operation, ignition timing correction via programmer interface, rotary valve cover clearance measurement, and jet pump impeller shaft radial play verification.

The document references torque specifications for critical engine fasteners, including cylinder head screws, crankcase halves, PTO flywheel retention, and magneto assembly components to ensure proper component sealing.

The manual provides comprehensive technical coverage of the twin-engine configuration with port and starboard systems, water cooling circuit arrangement with total-loss system design, and dual jet pump propulsion with reverse gate and weedless intake systems. Included are detailed procedures for engine top end service addressing cylinder head, piston assembly, and rotary valve timing; bottom end overhaul covering crankshaft alignment, bearing installation, and counterbalance shaft positioning; and complete exhaust system servicing including tuned pipe, manifold, muffler, and water injection cooling documentation.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Jet Boat manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)