1983-1986 Yamaha YTM/YFM200 & YTM225 Service Manual

Complete Clymer service guide covering engine, clutch, transmission, fuel, exhaust, electrical and suspension systems with troubleshooting, maintenance schedules, torque specs and detailed repair procedures for YTM200, YFM200 and YTM225 models.

Manual Preview

Sample pages from the 1983-1986 Yamaha YTM/YFM200 & YTM225 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha YTM200, YFM200, YTM225 — 1983–1986 Structured Automotive Collection for YTM/YFM Series Volume.

- Factory Power Framework: YTM200 and YFM200 models specify 196 cc (12 cu in) cylinder displacement is standardized to engine cylinder volume Architecture.

- Essential Operating Temps: For optimal operation, engine oil temperatures range from 40° F up to normal operating temperature is rated at SAE 20W/40 SE/SF viscosity Benchmarks.

- Key Cycle Rate: Maintenance service intervals specify every 6 months or 500 miles is calibrated to routine inspection and lubrication cycling Requirements.

- Primary Package Size: Tank fuel capacity reaches 1,500 cc (1.6 qt) for normal operation and 1,800 cc (1.9 qt) after complete engine overhaul specifies reservoir baseline Parameters.

- General Moment Values: Maximum compression pressure is specified to 9 kg/cm² (128 psi) standard with minimum acceptable 8 kg/cm² (114 psi) threshold sets engine performance Threshold.

- Approved Current Rating: Electrical system battery voltage is standardized to 12 volts DC for all models except 1983–1985 YTM200 provides complete charging capacity Range.

Professional Workshop Service Manual & Technical Specifications

Consolidated Shop Hydraulic Manual: ATV Clymer Edition: Yamaha YTM200, YFM200, YTM225 1983-1986 Maintenance Manual Field-Reference

Service-Level: YTM200, YFM200, YTM225 (1983-1986) // Diagnostic-Area: Multi-system / Mechanical Reference Logic // Service-Level: Comprehensive Clymer Publication Coverage.

| Integrated-Framework | System-Path | Framework |

|---|---|---|

| Engine Architecture | 4-Stroke Single-Cylinder Assembly | Complete technical documentation |

| Transmission Assembly | Clutch and Drive Systems | Full specifications provided |

| Fuel and Ignition | Carburetor and CDI Systems | See Chapter-by-chapter coverage |

Reference chapters include engine service and maintenance, carefully requiring clutch assembly procedures, fuel system documentation and carburetor adjustments, electrical system components and charging operations, and front suspension design layouts covering all model variations.

Systematic Protocol

Carefully requiring thorough documentation, the manual addresses the complete 4-stroke engine assembly, cylinder head service, camshaft and rocker arm configurations, piston ring installation, and crankshaft bearing maintenance. The document includes specifications for valve clearance adjustment, timing mark alignment, and compression testing protocols. Service procedures are documented for breaking down the engine within the frame, with emphasis on maintaining proper torque values and alignment during reassembly.

Core Benchmarks

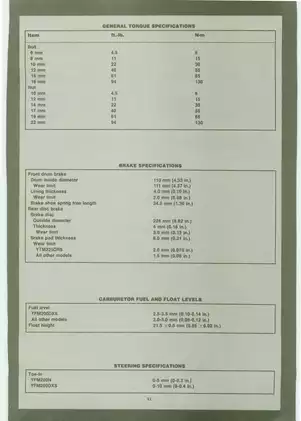

Service intervals are documented for engine oil changes, transmission fluid maintenance, and cooling system management. Component locations are identified for the air cleaner element, fuel shutoff valve, and spark plug removal. The manual provides comprehensive carburetor adjustment procedures, pilot screw tuning specifications, and float bowl fuel level calibration. Transmission assembly procedures are covered for both chain drive and shaft drive configurations, including detailed shift mechanism service and clutch plate inspection.

Precise Nexus

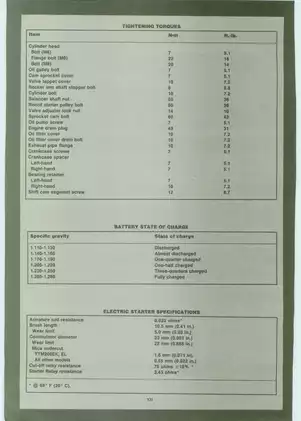

Service procedures are documented for the primary and secondary clutch assemblies, with detailed wear limit specifications for friction plates and spring tension. The manual includes alternator testing protocols, pickup coil resistance measurements, and ignition coil primary and secondary resistance values. Suspension adjustment techniques are specified for monoshock spring preload modifications and steering head bearing lubrication intervals.

Technical Protocol

Calibration requirements are specified for brake cable free play, throttle lever adjustment, and decompression lever positioning. The manual documents the drive chain adjustment procedure with specific free play limits and rear wheel alignment specifications. Electrical system documentation covers charging system output testing, voltage regulator operation, and starting system circuit functions. Tire pressure specifications and wheel bearing inspection procedures are thoroughly covered.

Engineered Logic-Path

Electrical system documentation covers the capacitor discharge ignition system, pickup coil trigger mechanisms, and ignition timing mark verification procedures. The document includes troubleshooting flowcharts for engine performance issues, charging system failures, and electrical component diagnostics. Fuel system documentation covers fuel tank removal, carburetor needle jet positioning, and main jet selection for altitude adjustment. The manual documents torque specifications for the crankshaft assembly to ensure proper fastener security.

FAQ

Customer Reviews

Read what our customers say about this Yamaha ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)