Perkins New 1000 Series Workshop Manual - 4 and 8 Cylinder Diesel Engines

Comprehensive 290-page Perkins Diesel Engine Workshop Manual covering AJ, AK, AM, AP, AQ, YG, YH, YK models. Includes all diagnostics, service, and parts information.

Manual Preview

Sample pages from the Perkins New 1000 Series Workshop Manual - 4 and 8 Cylinder Diesel Engines manual

Purchase & Download

Models Covered & Key Technical Specifications

Perkins New 1000 Series Workshop Manual: Diesel Engine AJ AK AM AP AQ AR AS YG YH YK Diesel Engine Workshop Manual - Comprehensive Diagnostics and Maintenance For Perkins Diesel Engines: Applied Sourcebook | Series Collection.

- Technical Specs: Engine Type: 4 cylinder, naturally aspirated, belt-driven coolant pump.

- Resolution Data: Engine Identification: AJ, AK, AM, AP, AQ, YG, YH, YK.

- Tension Specs: For optimal performance, 100 mm (3.937 in) defines the nominal bore diameter.

- Holding Capacity: For smooth operation, 45 N·m (33 lbf ft) signifies the clamping torque for connecting rods.

- Load Capacity: Throughput reaches 15.9 ppm Parameters.

- Dimensional Limits: Service Intervals: 240 hours are documented for routine maintenance Cycles.

Professional Workshop Service Manual & Technical Specifications

Complete Performance Training Manual: Diesel Engine Official Perkins AJ AK AM AP AQ AR AS YG YH YK Diesel Engine Workshop Manual - Comprehensive Diagnostics and Maintenance-Library

| Architecture-Focus: Factory specifications are documented for Architecture-Focus: Engine rebuild procedures are documented for Repair-Classification: Drivetrain specifications are addressed in Top of description | Identifier | Parameters | Validation-Data |

|---|---|---|---|

| Engine Type | 4 cylinder, naturally aspirated, belt-driven coolant pump | Production limits: 103 mm (4.055 in) bore diameter | |

| Engine Identification | AJ, AK, AM, AP, AQ, YG, YH, YK | Max. permissible bore wear: 0.15 mm (0.006 in) | |

| Piston and connecting rod assemblies | Max. permissible clearance: 0.002 in | Service limit: 0.004 in | |

| Crankshaft assembly | Width of groove: 0.006 in | Width of groove for third ring: 0.005 in | |

| Idler gear and hub | Outside diameter: 43.01/43.04 mm (1.693/1.695 in) | Diameter of bore for bush: 0.006 in | |

| Timing case and drive assembly | Diameter of hub of idler gear: 36.00/36.06 mm (1.417/1.419 in) | Clearance of bush in idler gear: 0.0009 in |

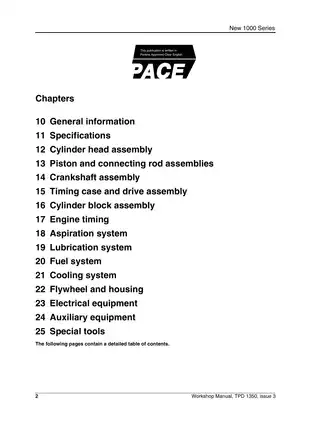

Following OEM groupings, the manual includes Engine identification, specifications, cylinder head assembly, piston and connecting rod assemblies, crankshaft assembly, timing case and drive assembly, cylinder block assembly, engine timing, aspiration system, lubrication system, fuel system, cooling system, flywheel and housing, electrical equipment, auxiliary equipment, special tools. Factory specifications are documented for proper engine function, ensuring optimal performance and longevity. Detailed procedures for disassembly, inspection, and reassembly of key engine components are provided, covering the entire engine from initial teardown to final assembly. The manual also documents torque specifications for critical engine fasteners to ensure proper assembly and prevent damage, such as corrosion joint prevention.

FAQ

Customer Reviews

Read what our customers say about this Perkins Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)