2008 Evinrude SE E-Tec 75, 90 HP Outboard Motor Service Manual

Technical reference for Evinrude E-TEC 75, 90 HP models including 20" and 25" shaft configurations. Documents engine management and fuel systems. PN 5006397

Manual Preview

Sample pages from the 2008 Evinrude SE E-Tec 75, 90 HP Outboard Motor Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Evinrude 75, 90 HP (5006397) – 2008 – Outboard Maintenance & Repair Manual Evinrude & Johnson Dossier | SE E-Tec Section.

- Documented Form Factor:** 79 cu. in. (1296 cc) specifies the engine displacement displacement Architecture.

- Technical Output Quality:** 4500 to 5500 RPM establishes the full throttle operating range Parameters.

- Universal Fastener Specs:** 3.601 in. (91.47 mm) indicates the standard bore diameter Baseline.

- Core Tolerance Values:** 1.3757 to 1.3762 in. (34.94 to 34.96 mm) defines the rod crankpin size Requirements.

- Rated Amperage Specs:** 25-Amp fully regulated indicates the alternator output output Threshold.

- Prescribed Unit Dimensions:** 2.588 in. (65.74 mm) signifies the stroke measurement Benchmarks.

Professional Workshop Service Manual & Technical Specifications

Definitive Training Hydraulic Manual: Outboard Motor Evinrude 2008 SE E-Tec 75hp/90hp 2008 - Outboard Maintenance & Repair Manual Calibration-Manual

| System-Identifier: Evinrude E-TEC 75, 90 HP Models // Diagnostic-Area: Outboard Motor / Engine Management Module (EMM) Logic // Product-Line: 2008 Evinrude E-Tec 75, 90 HP Manual. Table | Identifier | Operational-Logic | Calibration-Standards |

|---|---|---|---|

| Engine Type | In-line, 3 Cylinder, Two-Cycle | As specified by EMM | |

| Displacement | 79.1 cu. in. (1296 cc) | Calibrated to factory standards | |

| Bore | 3.601 in (91.47 mm) | Within tolerance ranges | |

| Stroke | 2.588 in. (65.74 mm) | Standardized measurements | |

| Fuel/Oil Control | EMM Controlled | Based on EMM programming | |

| Alternator | 25-Amp fully regulated | Standard output maintained |

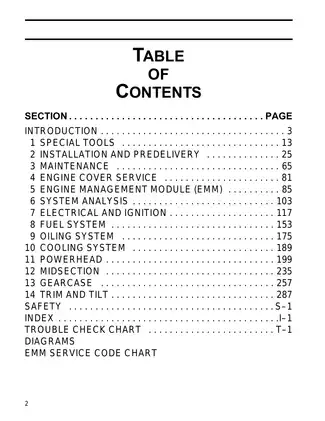

Technical chapters are organized around the following primary systems: Logically establishing ...

Engine Management Module (EMM) Diagnostics

This section focuses on the EMM's diagnostic capabilities. It covers software methods for engine temperature checks, including both software and pyrometer methods. It also details troubleshooting for idle operating temperatures, with specific guidance for conditions below the normal operating range. The manual includes procedures for inspecting and servicing the thermostat and pressure relief valve assemblies, ensuring proper cooling system function.

Electrical and Ignition System Testing

This comprehensive section covers the boat's electrical system, including detailed tests for the charging system, electric start circuit, and various remote control switches. It provides step-by-step instructions for troubleshooting issues with the ignition system, flywheel, stator, and starter. Specific tests for sensors, such as the Crankshaft Position Sensor (CPS) and Throttle Position Sensor (TPS), are included, along with guidance on interpreting EMM LED indicators to diagnose system status and potential faults.

Fuel System Components and Tests

This detailed section outlines the various components of the fuel system, including the fuel lift pump, fuel filter, vapor separator, fuel injectors, and fuel manifolds. It provides crucial information on fuel system hose routing and a circuit diagram for a clear understanding of the system's operation. The manual includes comprehensive tests for fuel system pressure, fuel injector performance, and fuel pump functionality, ensuring proper fuel delivery and engine operation. Careful attention is paid to the correct installation and servicing of these critical components to prevent fuel leaks and ensure optimal performance. The manual documents torque specifications for component assembly. Documented torque specifications for the fuel pump assembly are 24 to 36 in. lbs. (2.8 to 4.0 N·m).,

Cooling System Operation and Service

The manual provides a thorough examination of the cooling system's design and operation. It details the flow of water through the cylinder block, cylinder heads, EMM, and vapor separator, emphasizing the importance of proper water flow for engine performance and longevity. Troubleshooting procedures for low idle operating temperatures are included, along with guidance on servicing the thermostat and pressure relief valve assemblies. This section ensures the cooling system operates efficiently to prevent overheating. Torque specifications for the thermostat cover are 120 to 144 in. lbs. (13.5 to 16 N·m).

Oiling System Components and Tests

This section details the oiling system, covering the oil tank assembly, oil injection pump, and related electrical circuits. It includes critical information on low oil and no oil warning systems, as well as troubleshooting for cylinder and crankcase lubrication. The manual provides comprehensive tests for the oil injection pump's static performance, voltage, circuit resistance, and function. It also covers the correct procedure for oil distribution hose service and the testing of the low oil sending unit, ensuring proper lubrication for engine longevity. Torque specifications for the oil tank mounting screws are 30 to 42 in. lbs. (3.5 to 5 N·m).

FAQ

Customer Reviews

Read what our customers say about this Evinrude Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)