2001-2005 Aprilia RST1000 Futura S Service Manual

Complete workshop reference covering engine maintenance, fuel injection diagnostics, cooling system service. Includes electrical schematics, clutch/brake fluid procedures, transmission adjustments, chassis suspension tuning specifications across all model years.

Manual Preview

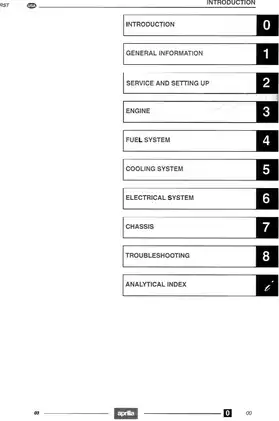

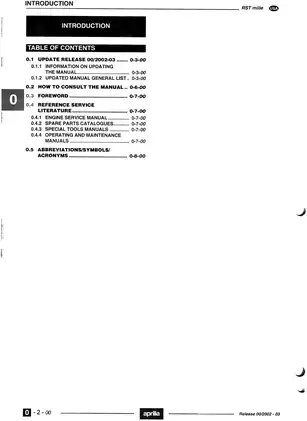

Sample pages from the 2001-2005 Aprilia RST1000 Futura S Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Aprilia RST1000 Futura S (8140176) — 2001–2005 Analytical Manual Repository | RST1000 Series Volume.

- Factory Ambient Limits: The air intake temperature range spans 15–35°C (59–95°F), establishing the environmental threshold Standards.

- Essential Cycle Rate: For hydraulic operation, the water pump achieves 23.8 gal/min (90 l/min) at 9000 rpm, determining the coolant circulation Baseline.

- Key Size Parameters: The engine displacement measures 60.878 cu in (997.62 cm³) — is calibrated to the 60° longitudinal V-type configuration Requirements.

- Primary Fastening Values: The crankshaft fastening nut is rated at 86.5 N·m (63.8 lb-ft), establishing secure engine assembly Threshold.

- General Charge Quantity: Fuel tank capacity reaches 5.28 US gal (20 l) including reserve, achieving the storage capability Mapping.

- Approved Heat Tolerance: Engine coolant thermostat valve opening temperature is 65 + 2°C (149 + 5°F) — corresponds to standard thermal protection Configuration.

Professional Workshop Service Manual & Technical Specifications

In-Depth Shop Technical Manual: Motorcycle Comprehensive Maintenance Guide: Aprilia RST1000 Futura S (2001-2005) Procedure-Database

Reference-Category: RST Mille, 2000-2002 models // Engine-Type: V-twin dual-cylinder, fuel injection and ignition system mechanics // Reference-Category: Service specifications including maintenance intervals, torque data, and specialized tools.

| Performance-Element | System-Path | Logic |

|---|---|---|

| Engine Assembly | Component location and removal procedures | Factory service specifications documented |

| Hydraulic Controls | Brake and clutch circuit documentation | Complete fluid capacity and bleeding data included |

| Fuel Delivery Network | Electronic injection management and pump operation | Sensor calibration and component testing reference |

| Chassis Components | Suspension, steering, and final drive systems | Adjustment procedures and bearing preload accuracy |

Integrated service sections encompass the engine and transmission systems, fuel system documentation, cooling system circuit management, electrical system architecture, and chassis suspension framework. The manual systematically details the clutch control system with PPC device operation, comprehensive brake system hydraulics for front double-disc and rear single-disc configurations, and drive chain maintenance specifications for the sealed O-ring endless chain assembly. Service procedures are documented for ignition system timing advance, spark plug gap adjustment, and electronic control unit sensor integration including crankshaft position detection, throttle valve mapping, and coolant temperature compensation.

Diagnostic Sequences

Component locations are identified for all major assemblies including the electronic control unit position, alternator mounting, ignition coil placement, fuel pump relay location, starter motor configuration, and battery installation point. The manual provides detailed identification of electrical connector types, wire color coding standards, and diagnostic test point access for troubleshooting ignition and injection system faults. Specifications for all fastener tightening torques are systematically organized by component category, including engine block fastening points, suspension attachment specifications, frame-to-component bolting patterns, and body panel retention data with corresponding LOCTITE adhesive application requirements.

Modular Topology

Calibration requirements are specified for idle speed electronic stepper motor adjustment, fuel injection timing control through manifold pressure compensation, spark advance curve programming based on engine speed and throttle position, and cylinder synchronization using manifold vacuum measurement techniques. The document documents torque specifications for the cylinder head fasteners to ensure proper bearing preload accuracy. Replacement component identification includes part numbers for spark plugs with platinum electrodes, brake fluid specifications with DOT rating compliance, coolant mixture ratios with antifreeze concentration tables, and engine oil viscosity classification matching thermal operating ranges. Maintenance interval schedules progress from initial service at 625 miles through 4,687-mile and 14,000-mile checkpoint procedures, with competitive use modification recommendations for accelerated replacement cycles.

Core Standard

Electrical system documentation covers alternator open-circuit voltage generation measurement, charging system regulator load response, voltage stabilization under varying engine speed conditions, and recharging system wiring diagram circuit paths. Battery activation procedures, maintenance-free battery care instructions, and extended storage protocols are included alongside jump-starting procedures with polarity-sensitive cable connection sequencing. Engine oil pressure monitoring through dashboard LED warning illumination, fuel pump relay circuit validation, injection system power supply verification, and ignition coil primary and secondary winding resistance testing are referenced in the troubleshooting section.

Precise Interface

Suspension service documentation covers upside-down hydraulic fork damping adjustment, spring preload modification using notch-indexed adjustment screws, and rear shock absorber compression and extension tuning for variable riding conditions. Steering head bearing play inspection and adjustment utilizing specialized socket wrenches, swinging arm pivot bearing preload verification, and rear suspension linkage bearing condition assessment procedures are systematically detailed. The manual provides comprehensive gear ratio tables for the six-speed transmission, primary drive ratios, and final chain reduction documentation for performance calculation and diagnostics.

Operational Framework

Component specifications reference frame identification number location, engine serial number engraving position, and warning adhesive label placement for regulatory compliance documentation. Specifications encompass overall vehicle dimensions, saddle height parameters, wheelbase measurement, minimum ground clearance distance, and curb weight distribution data with tire pressure specifications for solo and loaded configurations. Fuel tank capacity including reserve volume, coolant system charge quantity, engine oil change volumes, fork oil per-leg capacity, and brake fluid reservoir specifications are tabulated with measurement unit alternatives in both metric and imperial standards.

Release Notes: This service manual covers the 2001-2005 production model years with progressive release numbering (Release 00/2002-03). The document structure follows technical service literature standards with section divisions, chapter organization, and paragraph cross-referencing for maintenance operation sequencing and component identification protocols.

FAQ

Customer Reviews

Read what our customers say about this Aprilia Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)