1947-1956 Ferguson TE-A20 TE-C20 TE-D20 TE-E20 TE-F20 TE-H20 Service Manual

Engine specifications, hydraulic systems, cooling, fuel injection with detailed valve timing and repair procedures for Ferguson diesel and petrol tractor models.

Manual Preview

Sample pages from the 1947-1956 Ferguson TE-A20 TE-C20 TE-D20 TE-E20 TE-F20 TE-H20 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Ferguson TE-A20, TE-C20, TE-D20, TE-E20, TE-F20, TE-H20 Series — 1947–1956 Integrated Functional Vault | Ferguson TE Series Tractor Archive.

-

Approved Amperage Specs: Starter motor operates at 12 volts with 38 ampere-hour capacity at 10 hour discharge rate is rated at the minimum current threshold for cranking duty Bounds.

-

Baseline Thermal Envelope: Engine coolant thermostat crack opens at 60°C (140°F) and reaches full open at 93°C (199°F), providing the maximum temperature safety margin for normal operation Topology.

-

Primary Production Rate: Fuel tank capacity reaches 8 Imperial gallons (36 litres) including 1 Imperial gallon (4.5 litres) held in reserve is specified as the total fuel storage allocation Matrix.

-

General Imaging Specs: Oil pump delivers approximately 3.95 gallons (16.94 litres) per minute at 2,000 engine rpm at 50 pounds per square inch (3.52 kg/sq. cm.) pressure, representing maximum continuous delivery Standards.

-

Essential Fluid Capacity: Engine sump requires 12 pints (6.8 litres) of lubricating oil to reach full capacity is calibrated to maintain bearing film thickness Margin.

-

Operational Output Rating: Maximum engine belt horsepower achieves 28.2 at rated speed for the petrol engine variants is designated as peak mechanical power available Protocol.

Professional Workshop Service Manual & Technical Specifications

Definitive Shop Manual: Ferguson TE-A20 TE-C20 TE-D20 TE-E20 TE-F20 TE-H20 Tractor Service Manual - Comprehensive Repair Procedures (1947-1956) Transmission-Guide

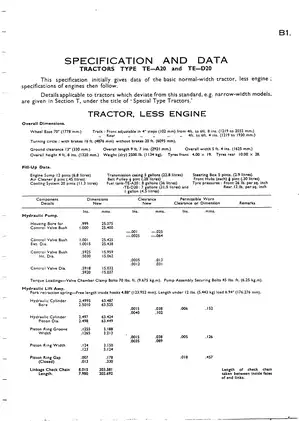

Coverage-Scope: Ferguson TE-A20, TE-C20, TE-D20, TE-E20, TE-F20, TE-H20 Series (1946-1956) // Documentation-Type: Service and Technical Reference Manual / Petrol, Vaporising Oil, Lamp Oil, and Diesel Engine Systems // Specification-Class: Complete dimensional data, torque references, and component assemblies.

| Service-Nexus | Baseline | Context |

|---|---|---|

| Engine Specifications | Bore, stroke, displacement, compression ratios | Standard and modified variants documented for each model |

| Transmission Systems | Gear ratios, bearing clearances, backlash tolerances | All shifting mechanisms and component specifications included |

| Hydraulic Systems | Pump flow rates, valve pressures, cylinder dimensions | Lift assembly and control valve specifications provided |

| Fuel Delivery | Tank capacity, filter assemblies, carburetor adjustments | Zenith, Schebler, Holley, and CAV injection systems covered |

| Cooling Systems | Radiator capacity, thermostat settings, water pump data | Engine-specific cooling parameters for all variants |

The service manual covers cylinder head assembly including combustion chamber layout, valve timing procedures, and tappet clearance specifications. Engine sections encompass lubrication pathways through the oil gallery system, oil filter servicing requirements, and crankshaft bearing mounting procedures. The document provides detailed information on timing chain adjustment, camshaft positioning, and synchronization between crankshaft and injection pump elements.

Structured Parameters

Strategically demanding coverage of the petrol engine incorporates fuel system components, including sediment bowl assembly, air cleaner operation, and choke control linkage. The manual documents manifold attachment procedures, exhaust system components, and breather valve functionality. All carburetor models—including variable main jet and min/max adjustable types—are addressed with reference to float settings, idle mixture screw positions, and slow running jet configurations.

Integrated Nexus

Clearance measurements are addressed for connecting rod alignment, gudgeon pin bush reaming, and piston ring gap verification. The document references valve guide specifications and seat cutting procedures, including glaze breaker and narrowing cutter applications. Specifications for oil pump rotor dimensions, camshaft journal tolerances, and big end bearing liners are systematically documented for maintenance and replacement purposes.

Core Topology

Cooling system descriptions cover water circulation patterns, thermostat bellows operation, and valve lift characteristics. The manual includes diesel engine documentation featuring comprehensive fuel injection pump data, including spill timing references, phasing procedures, and governor operation. Injector nozzle specifications, break-away pressure settings, and spray formation characteristics are documented with reference to pre-combustion chamber design.

Technical Standard

Repair information is provided for cylinder sleeve removal and replacement, including liner flange gasket seating and upper block clearance verification. The document addresses water pump bearing assembly disassembly, impellor seal configurations, and coupling alignment procedures. Rocker assembly dismantling instructions reference pedestal location, spring mounting, and valve adjuster screw positioning.

Strategic Methodology

Testing requirements are specified for cylinder head compression evaluation and thermostat valve opening temperatures. Verification procedures are included for valve grinding results, using lead pencil marking techniques to confirm gas-tight sealing. Special procedures are addressed for pre-combustion chamber lower half renewal, including drilling jig operation and chamber orifice finishing.

The manual documents torque specifications for cylinder head nuts, ensuring proper thermal expansion compensation and maintained compression integrity. References throughout indicate specification tables containing bolt torque values, spring load ratings, and bearing preload requirements distributed across the technical sections.

FAQ

Customer Reviews

Read what our customers say about this Massey-Ferguson Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)