2006-2012 Honda TRX680FA & TRX680FGA Service Manual

Comprehensive service procedures for Honda's 674cc single-cylinder Rincon ATV with PGM-FI fuel injection, automatic transmission, selectable 4WD system, and dual hydraulic disc brakes — 596 pages of factory technical specifications.

Manual Preview

Sample pages from the 2006-2012 Honda TRX680FA & TRX680FGA Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda TRX680FA & TRX680FGA — 2006–2012 Authorized Technical Resource | Rincon Series Repository.

- Authorized Displacement Data: 674.9 cm³ (41.19 cu in) is specified as the single-cylinder engine volume Sequences.

- Critical Power Output: For optimal performance, the engine produces maximum horsepower at 6200 rpm representing the rated output Baseline.

- Operational Torque Specification: 145 N·m (107 lb-ft) at 5000 rpm — controls the crankshaft rotational force Requirements.

- Established Fuel Tank Capacity: The main tank requires 17 liters (4.5 US gal) for 2006–2007 models carrying standard fuel reserves Threshold.

- Measured Oil Pressure Data: Line pressure reaches 785 kPa (8.0 kgf/cm², 114 psi) at 5,000 rpm (minimum) governing hydraulic system operation Mapping.

- Maximum Tire Pressure Specification: Front tires are configured at 30 kPa (0.30 kgf/cm², 4.4 psi) standard cold pressure maintaining proper vehicle handling Configuration.

Professional Workshop Service Manual & Technical Specifications

Authoritative Training Workshop Manual: ATV Honda TRX680FA & TRX680FGA Service & Repair 2006-2012 - Comprehensive ATV Workshop Manual Electrical-Reference

Assembly-Group: TRX680FA (2006-2012), TRX680FGA (2006-2012) // Series-Validation: Automatic Transmission System / Drivetrain Logic // Service-Level: Professional workshop documentation for qualified technicians.

| Specification | Operational-Logic | Calibration-Standards |

|---|---|---|

| Engine Type | Single-cylinder, OHV, liquid-cooled | 674.9 cc displacement, 9.2:1 compression |

| Transmission System | 3-speed automatic with torque converter | Shift points documented for AUTO/ESP modes |

| PGM-FI System | Programmed fuel injection with self-diagnostic | Complete sensor specifications included |

| Electrical Architecture | Integrated PCM with ECM and TCM | Full wiring diagrams for all circuits |

| Suspension Geometry | Double-wishbone front and rear | Complete alignment and torque data |

| Drive Modes | Selectable 2WD/4WD with front final clutch | Electronic control system parameters |

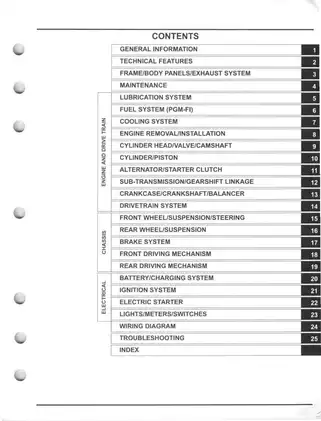

Featuring a modular arrangement of system components, the manual encompasses engine removal and installation procedures, coupled with documentation addressing cylinder head, valve, and camshaft assemblies. Major sections focus on lubrication system architecture, fuel system diagnostics with PGM-FI troubleshooting protocols, and comprehensive cooling system maintenance schedules that guide technicians through radiator service and thermostat replacement workflows.

Engineered Protocol

Removal procedures are documented for the following subsystems: frame and body panel construction, exhaust system routing and gasket specifications, transmission components including the sub-transmission forward-neutral-reverse selector mechanism, and all major engine assemblies requiring systematic disassembly. The manual provides detailed procedural sequences for crankcase separation, crankshaft bearing inspection, and balancer assembly alignment verification, ensuring technicians understand the precise sequencing required for complex rebuild operations.

Strategic Interface

Technical specifications are provided for all major mechanical components including valve clearance tolerances, piston ring gap measurements, connecting rod clearance verification, and bearing runout limits that define acceptable service conditions. Comprehensive torque values are documented throughout, including standard fastener specifications, engine mounting hardware requirements, transmission case bolts, and frame attachment points that ensure proper reassembly and structural integrity across all model variants.

Integrated Protocol

Factory specifications are documented for the drivetrain system encompassing the three-speed automatic transmission with shift solenoid valve operation, torque converter stall ranges and coupling phase behavior, and the selectable 4WD system front final clutch engagement parameters. Complete oil pressure specifications define line pressure requirements, individual shift clutch pressure thresholds for first, second, and third gear ranges, and emergency valve operating conditions for fail-safe transmission retention in 2nd gear mode.

Diagnostic Logic-Path

Engine rebuild procedures are documented for cylinder head disassembly and reassembly, including valve spring compression specifications, stem seal installation, rocker arm assembly sequences, and push rod alignment verification that prevent incorrect installation. The manual includes detailed inspection protocols for measuring valve guide bore diameters, stem-to-guide clearances, valve seat widths, and proper refacing angles using 45-degree, 32-degree, and 60-degree cutting tools to restore valve seating surfaces.

Engineered Methodology

Drivetrain specifications are addressed in comprehensive sections covering the automatic transmission self-diagnostic system with diagnostic trouble code interpretation, symptom-based troubleshooting flowcharts for shift failures and creep control malfunction, and complete circuit testing procedures for shift solenoid valves A and B that direct hydraulic pressure routing. The document includes troubleshooting matrices for oil pressure verification, transmission control circuit inspection, and PCM power and ground line continuity testing that isolate electrical faults from mechanical component failures.

The manual documents torque specifications for the primary driven gear lock nut to ensure proper front final clutch engagement, with specifications for component alignment retention and secure fastener installation throughout the powertrain assembly.

Document Features:

- 596 total pages with 607-page comprehensive coverage

- 28 detailed service chapters organized by system location

- Complete electrical wiring diagrams and cable routing specifications

- Diagnostic trouble code index with detailed circuit troubleshooting procedures

- Maintenance schedule table with service interval frequencies and part replacement criteria

- Tool specifications and special equipment requirements for advanced procedures

- Emission control system documentation including PGM-FI system diagrams and fuel permeation control technologies

- Oil viscosity recommendations and lubrication point location charts

- Cooling system pressure test procedures and antifreeze concentration standards

FAQ

Customer Reviews

Read what our customers say about this Honda ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)