2002 Xerox Phaser 6200/6200B/6200N/6200DP/6200DX Service Manual

Complete color laser printer repair guide with error codes, troubleshooting procedures, and FRU parts lists. Essential technical reference for service technicians covering all five Phaser 6200 configurations and optional high-capacity feeder assembly.

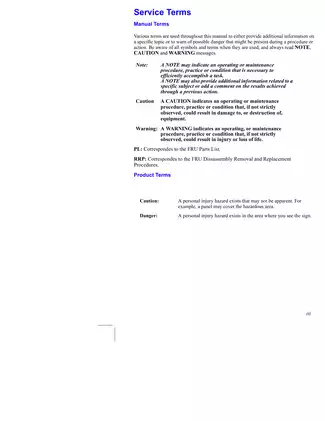

Manual Preview

Sample pages from the 2002 Xerox Phaser 6200/6200B/6200N/6200DP/6200DX Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Xerox Phaser 6200, 6200B, 6200N, 6200DP, 6200DX — 2002 Comprehensive Technical Archive | Phaser 6200 Series Portfolio.

-

Authorized System Volume: The printer supports 64 Mbytes of standard memory, with optional memory configurations reaching up to 512 MB total is calibrated to provide flexible imaging Specifications.

-

Published Spacing Data: For optimal registration, the color registration control system supports adjustment settings ranging from -7 to +7 units (left to right) establishes precise color alignment Baseline.

-

Reference Wattage Specs: Maximum print mode power consumption reaches 850 W or less for both 100/115 VAC and 240 VAC supplies defines the electrical Requirements.

-

Established Cold Start Limits: The warm-up time is designed for 30 seconds from cold start (power off condition) achieves rapid operational Threshold.

-

Measured Form Factor: Print resolution is specified as 2400 x 600 dpi (enhanced mode) with standard draft capability of 600 x 600 dpi represents addressable output Mapping.

-

Core Liquid Volume: The toner cartridge standard capacity reaches 3,000 pages (5% coverage) defines consumable yield Configuration.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Operator's Manual: Copier Xerox Phaser 6200, 6200B, 6200N, 6200DP, 6200DX 2002 - Comprehensive Service Manual for Color Laser Printer Repair-Index

Specification-Class: Phaser 6200 (2002), Phaser 6200B (2002), Phaser 6200N (2002), Phaser 6200DP (2002), Phaser 6200DX (2002) // Product-Line: Color Laser Printer Systems / Four-Tandem Drum Electrophotographic Logic // Specification-Class: Imaging unit life 30,000 pages; transfer roller and waste box 15,000 pages; fuser assembly 60,000 pages.

| Component Category | System Overview | Documentation Reference |

|---|---|---|

| Printing Process | Four-tandem drum electrophotographic system with intermediate drum transfer rolls (IDTs) and heat fusing | Complete specifications provided |

| Color System | Cyan, Magenta, Yellow, Black (CMYK) toner cartridges with simultaneous four-beam laser scanning | Documented in chapters 8-9 |

| Print Specifications | Resolution from 600 x 600 dpi (standard/draft) to 2400 x 600 dpi (enhanced); 1200 x 1200 dpi (photo mode available on DP/DX) | Complete specifications provided |

Engineering chapters address General Information and Printer Overview, then proceed through Error Messages and Codes, and Troubleshooting procedures, followed by Test Prints and Adjustments, and subsequently outline Cleaning and Maintenance requirements, FRU Disassembly and Replacement procedures, and detailed Theory of Operation documentation, concluding with Plug/Jack Locator Maps and comprehensive Wiring Diagrams for systematic diagnosis.

Structured Architecture

Sequentially requiring attention, the manual encompasses functional specifications detailing printing process capabilities, media handling parameters, and environmental operating conditions. The document profiles the printer's four distinct configurations: the base 6200B model with 64 Mbytes memory and 600 x 600 dpi resolution; the networking-enabled 6200N with 128 Mbytes and enhanced 2400 x 600 dpi capability; the feature-rich 6200DP including auto-duplexing and PDF support; and the comprehensive 6200DX equipped with 256 Mbytes, 1000-sheet High-Capacity Feeder, and internal hard drive. Proper layout guidance is provided for all paper tray configurations, media types from standard 65 g/m² plain paper through specialty transparencies, and weight specifications supporting duplex and simplex output modes.

Comprehensive Nexus

Tool requirements are listed for qualified service personnel performing maintenance and diagnostic procedures within the printer's internal assemblies. The service manual includes extensive error message documentation with corresponding fault codes, enabling technicians to identify specific component failures through front panel display analysis. Maintenance guidelines are included for routine cleaning cycles, roller care, and toner system inspection. Documentation encompasses the system boot sequence including Power On Self Test (POST) diagnostics, fault reporting through LED blink patterns and front panel displays, and detailed troubleshooting pathways for electrical, mechanical, and consumable-related issues.

Precise Protocol

Installation guidelines are provided for all Field Replaceable Units (FRUs) through 37 detailed disassembly and removal and replacement procedures (RRPs). The manual documents torque specifications for fasteners to ensure proper mechanical assembly and prevent component damage during service operations. Wiring diagram coverage includes the main printer circuit, power supply distribution, paper tray control systems, drive section motor controls, developer and toner management circuits, fuser assembly thermal control, laser unit exposure system, xerographic transfer and charging systems, and optional High-Capacity Feeder integration points.

Technical Standard

The document includes comprehensive parts list identification for over 250 field replaceable components, organized by functional assembly groups including covers, paper feed mechanisms, chute assemblies, drive systems, electrical components, and harness assemblies. Service diagnostic capabilities are outlined with detailed descriptions of test functions for motor and fan operation, sensor and switch status verification, clutch and solenoid actuation, and maintenance cycles for imaging unit cleaning. The manual provides reference data for CRC (Customer-Replaceable Consumable) life counters tracking toner cartridge consumption, imaging unit page count, fuser assembly usage, and transfer roller waste accumulation for proactive maintenance planning.

Comprehensive Standard

OEM guidelines are included for color calibration, color registration adjustment using -7 to +7 unit offsets, and margin calibration procedures to optimize print quality and eliminate image misalignment. The document details the automatic density control system measuring transfer roller toner density through the CTD (ADC) sensor, pixel count dispense control calculating consumed toner based on video signal analysis, and admix mode activation for high-humidity environment compensation. Paper path routing is documented from selection through trays 1, 2, and 3 of the optional High-Capacity Feeder, through the registration chute assembly with metal and rubber roller tension adjustment, across the imaging unit intermediate transfer units, and through the transfer roller assembly and fuser heat-fusing mechanism to final output.

The manual documents torque specifications for critical fastening points and mechanical assemblies to ensure proper rotational loosening prevention and secure component mounting throughout the print engine assembly.

FAQ

Customer Reviews

Read what our customers say about this Xerox Copier manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)