Kubota Z500-B manual: Z600B, ZH600-B, D650-B, D750-B engine

Manual Preview

Sample pages from the Kubota Z500-B manual: Z600B, ZH600-B, D650-B, D750-B engine manual

Purchase & Download

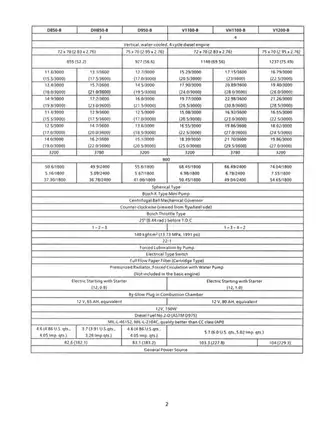

Models Covered & Key Technical Specifications

-

Kubota Z500 Z600 ZH600 D650 D750 (Engine-Series) — [1980–1999] Document Repository | Archive-Vault ◊ Z500-A Z600-A ZH600-A D650-A D750-A D850-A Workshop Library (Technical-Master).

-

Advanced Parameter: 326 Pages establishes the comprehensive scope for the complete overhaul of all identified engine variants.

-

Technical Data-Point: Water-Cooled Diesel defines the cooling architecture for the specified three-cylinder and two-cylinder configurations.

-

Specific Measurement: Factory Clearance is required for the precise adjustment of the valve train and crankshaft bearing assemblies.

-

Essential Rating: OEM Specification must be maintained to ensure the operational integrity of the fuel injection pump and governor system.

Professional Workshop Service Manual & Technical Specifications

Integrated Technical Manual Reference: Kubota Z500 Z600 ZH600 D650 D750 Engine Series

Kubota Z500 Z600 ZH600 D650 D750 (Technical-Manual-Edition) — [1980–1999]

Operational Protocol

Governing operational sequences across the multi-cylinder platform requires strict adherence to the manufacturer-provided framework. Within the component context, internal mechanical synchronization relies on the precise alignment of rotating assemblies as outlined in the original engineering data. To ensure system alignment, the repository establishes the necessary conceptual relationships between stationary and moving internal parts. Appropriately qualified personnel utilize these records to confirm structural integrity during major overhaul intervals. Technical validation follows the established logic path for diesel combustion cycles without deviation from primary design intent.

Systematic Architecture

| Component Category | System Grouping | Document Scope Areas |

|---|---|---|

| Core Engine Blocks | Thermal Management & Cooling | Dimensional Integrity & Castings |

| Valve Train Assemblies | Lubrication & Oil Distribution | Timing Calibration & Gear Trains |

| Fuel Injection Systems | Aspiration & Air Intake | Governor Logic & Delivery Paths |

Modular Methodology

Rigorously validating system logic necessitates a comprehensive understanding of the interface between fuel delivery and governor response. To maintain structural longevity, lubrication circuits must operate under conditions defined by the manufacturer within the archival records. Beyond the physical assembly, the maintenance framework categorizes essential interfaces that govern thermal dissipation across the cylinder head and block. Procedural execution requires appropriate technical qualification to interpret the complex interplay of mechanical tolerances. Standards documented in the original archive serve as the definitive baseline for all assessment activities.

Comprehensive Parameters

Within the combustion chamber environment, material specifications and surface finish requirements are defined by the manufacturer within the original documentation. To facilitate reliable operation, the blueprint-vault provides the categorical breakdown of all critical sub-systems and their respective assembly hierarchies. Carefully analyzing the integration of electrical charging components ensures that external ancillary systems remain compatible with the core engine architecture. Operational limits follow OEM-defined parameters as captured in the technical repository for the specified engine series. Professional technicians reference these organizational structures to maintain the continuity of the original manufacturing standards throughout the equipment lifecycle.

FAQ

Customer Reviews

Read what our customers say about this Kubota Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)