2004 JCB 926, 930, 940 Rough Terrain Fork Lift Service Manual

Complete service guide for JCB 926, 930, and 940 Rough Terrain Fork Lifts. Covers all maintenance and repair procedures for optimal performance. PN 9803/5100-16

Manual Preview

Sample pages from the 2004 JCB 926, 930, 940 Rough Terrain Fork Lift Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

2004 JCB 926, 930, 940 Rough Terrain Fork Lift Service Manual

Complete service guide for JCB 926, 930, and 940 Rough Terrain Fork Lifts. Covers all maintenance and repair procedures for optimal performance. PN 9803/5100-16 | Series Rough Terrain Fork Lift Kit

- Prescribed Load Capacity: 2700 kg establishes the maximum operational limit Framework.

- Standard Environmental Range: For optimal operation, -15C to 40C defines the operational temperature Bounds.

- Core RPM Specs: 2000 RPM is the rated maximum engine speed Topology.

- Rated Installation Footprint: The machine requires 18.3 cubic meters for standard operational placement Norms.

- Calibrated Threaded Fastener Data: 40 Nm torque is the recommended setting for critical fasteners Bounds.

- Nominal Voltage Specs: The electrical system operates at 12V, signifying the standard power Topology.

Professional Workshop Service Manual & Technical Specifications

Commercial Shop Parts Manual: JCB 926, 930, 940 Rough Terrain Fork Lift 2004 Factory-Standards

System-Coverage: 2004 JCB Forklift Models // Validation-Data: Rough Terrain Fork Lift / Dieselmax Engine Logic // Technical-Domain: All Machine Systems

| Technical Specs Table | Assessment-Element | Parameters | Framework |

|---|---|---|---|

| Engine Model | JCB Dieselmax | Engine | |

| Year of Manufacture | 2004 | System | |

| Transmission | 4WD | Drive | |

| Mast Type | Duplex | Lift | |

| Operating Hours | 6000 | Service | |

| Fuel Type | Diesel | System |

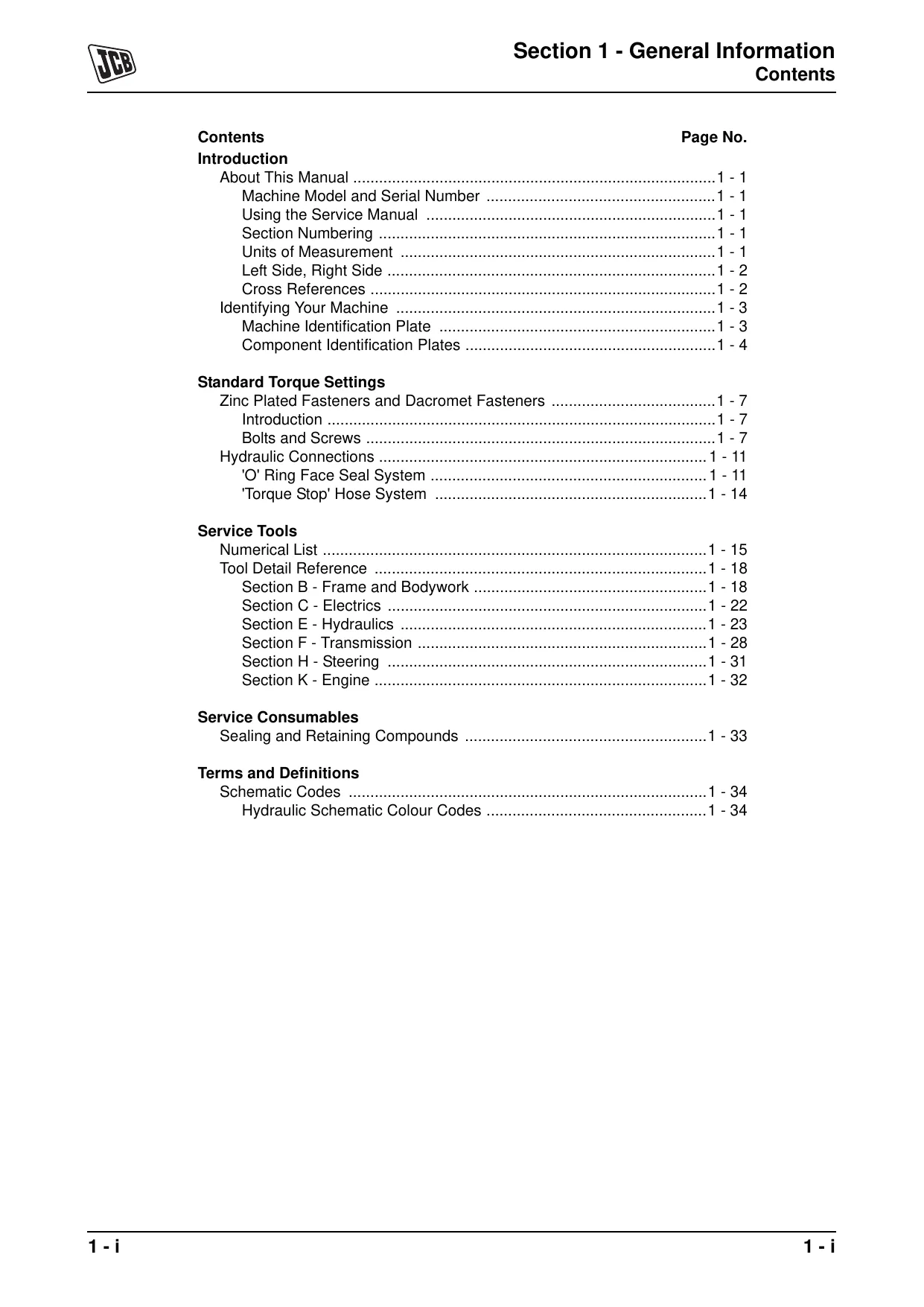

TOC Summary Block Service sections detail:

- Routine Maintenance

- Engine Oil and Filter Change

- Fuel System Procedures

- Hydraulic System Checks

- Transmission Oil Level

Prose Paragraphs Properly demanding maintenance ensures machine longevity and peak operational efficiency. This manual provides comprehensive guidance for servicing the JCB 926, 930, and 940 Rough Terrain Fork Lifts.

Engine Servicing

Procedures cover engine oil and filter changes, coolant checks, and air filter maintenance, ensuring the engine operates optimally. The manual details checks for all engine types, including JCB Dieselmax models.

Drivetrain and Hydraulic Systems

Guidance is provided for checking and maintaining transmission oil levels, changing filters, and inspecting hydraulic systems. Proper care of these components is crucial for smooth operation and longevity.

Chassis and Electrical Maintenance

This section details important checks for the carriage, mast, chains, and electrical systems. Adherence to these procedures ensures the safe and reliable operation of the forklift.

Torque specifications are provided for critical components to ensure proper assembly and prevent damage, contributing to bearing preload accuracy.

FAQ

Customer Reviews

Read what our customers say about this JCB Forklift manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)