Hyster C203 Forklift Service Manual

Detailed service documentation for Hyster C203 forklifts, covering brake system repairs and maintenance. Includes procedures for master cylinder and service brake assemblies. Part No. 1482623.

Manual Preview

Sample pages from the Hyster C203 Forklift Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Hyster C203 Forklift Service Repair Manual: Hyster C203 Forklift Brake System Documentation-Framework Brake System Service Manual | Brake System Kit.

- Approved Play Limits: 22 N•m (16 lbf ft) establishes the torque for oil outlet screws Standards.

- Baseline Electrical Specs: For brake adjustments, 74 mm (2.9 in.) defines the brake pedal height Protocol.

- Verified Climate Specs: 10 ±2 N•m (88 ±17 lbf in) -- signifies the torque for capscrews on strap plate Matrix.

- Designated Travel Rate: The wheel cylinder requires 2.5 ±1.5 N•m (22 ±13 lbf in) for bleeder screw tightness Standards.

- Certified Print Quality: Maximum specification reaches 182.27 mm (7.18 in.) Standards.

- Reference Spacing Data: The brake drum requires 68 N•m (50 lbf ft) for initial nut tightening Norms.

Professional Workshop Service Manual & Technical Specifications

Hyster C203 Forklift Service Repair Manual: Hyster C203 Forklift Brake System Documentation-Framework

Brake System Service Manual | Brake System Kit.

Validation-Data: Hyster C203 Forklift Service Manual // Asset-ID: 1482623 / Brake System Logic // Validation-Data: Forklift Brake System.

| Service-Nexus | Diagnostic-Logic | Calibration-Standards |

|---|---|---|

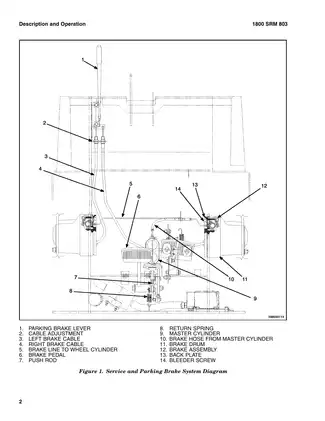

| Brake System Description | Master Cylinder Repair | Brake System Air Removal |

| Service and Parking Brakes Repair | Brake Pedal Adjustment | Troubleshooting |

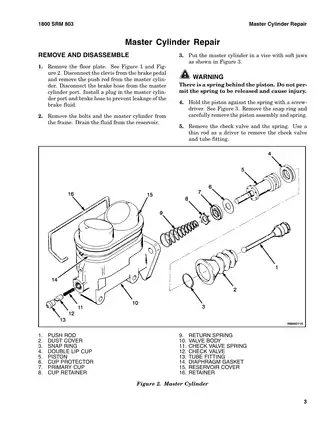

Factory procedures are documented for hydraulic system components and brake operation. This manual provides comprehensive guidance for maintenance and repair, ensuring the longevity and safety of your Hyster forklift. It details procedures for the master cylinder, brake shoes, wheel cylinders, and parking brake system, offering clear instructions for each component. Diagnostic and troubleshooting sections are included to address common issues, facilitating efficient problem resolution and minimizing downtime. The manual covers adjustments for brake pedal height and service brakes, ensuring precise calibration and optimal functionality for safe operation. It also provides detailed information on troubleshooting common brake system problems.

FAQ

Customer Reviews

Read what our customers say about this Hyster Forklift manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)