Hyster manuals for lift trucks, warehouse equipment, and series-specific documentation

Hyster coverage is easiest to navigate when you treat the manual title as a fit statement: it usually ties to a particular truck series, configuration, and build range. This brand page gathers Hyster-related PDFs that can help you line up the right document with the exact unit you’re responsible for—whether that’s a single truck or a mixed fleet.

Decode the identifiers that separate “similar” Hyster trucks

Many Hyster names repeat across generations, so the most reliable match signals tend to be short codes and ranges, such as:

- Truck model / series code (the fastest way to avoid near-miss matches)

- Production or serial range when it’s stated

- Power type (electric vs. internal combustion) and any platform notes tied to it

- Capacity class and mast family when the listing calls them out

- Region / market variant notes if included in the scope

What the listings usually provide (scope preview)

Hyster PDFs in this section commonly organize information as reference material, for example:

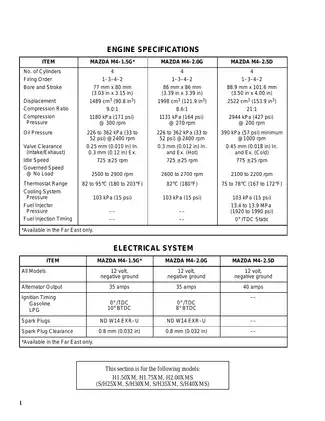

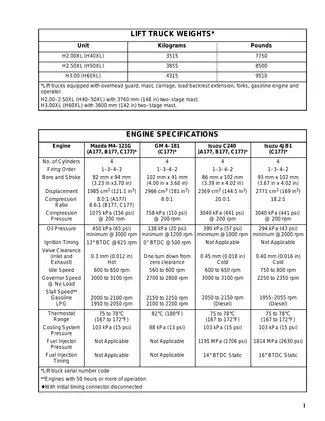

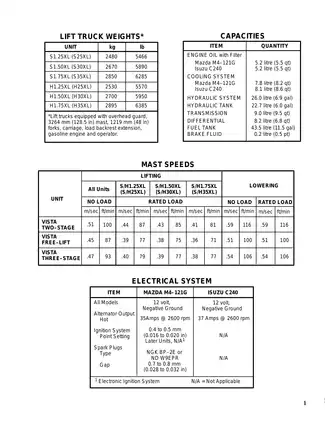

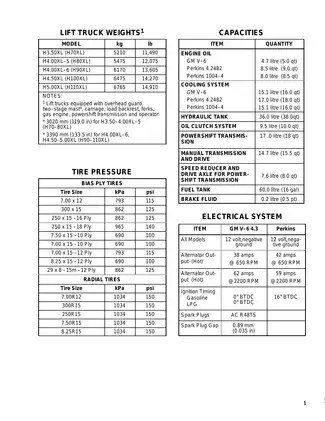

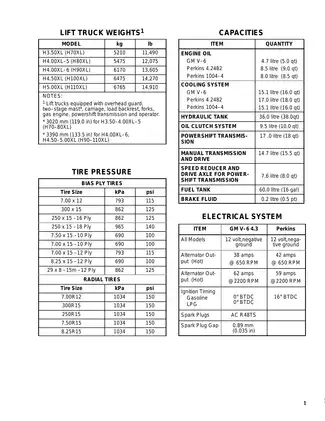

- model identification pages and specification blocks

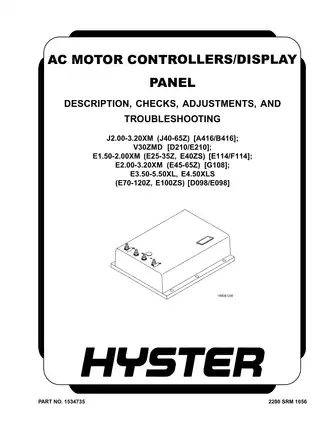

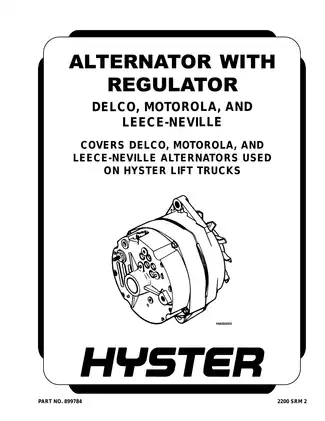

- system coverage grouped by platform family

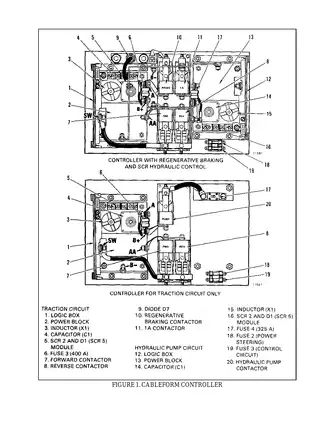

- hydraulic and electrical reference pages (schematics/diagrams where included)

- component mapping and illustrated breakdowns when present

- inclusions/exclusions that clarify which variants are covered

Picking between service-style vs. parts-style documents

Not every listing serves the same purpose. Use the label and scope notes to decide what fits your intent:

- If you need broad platform reference, look for service/workshop coverage tied to a specific series and build range.

- If you need component identification, prioritize parts-focused listings that emphasize assemblies and diagrams (when included).

- If a listing bundles multiple truck codes, treat that as a hint that the document is family-based rather than single-model.

Reduce mis-matches in multi-truck environments

If you manage several Hyster units, it helps to group your selection by:

1) series code family first,

2) then power type,

3) then the tightest applicable build/serial range.

That ordering usually mirrors how the documents draw their coverage boundaries.

When you can’t find an exact title match

If your truck code isn’t shown exactly as you expect, try searching within the site using the series code + a build range cue (year span or serial range, if known). Small differences in suffixes and ranges often explain why two listings that look alike are actually aimed at different configurations.

Hyster Manuals (37 total results)

Hyster A177, H40XL, H50XL, H60XL Repair Manual

1998-2004 Hyster Lift Truck Service Manual

1981-1986 Hyster H40J H50J H60JS Lift Truck Service Repair Manual (F003)

1998-2005 Hyster H2.00-3.20XM, H40-65XM, S2.00-3.20XM, S40-65XM Service Manual

2003-2005 Hyster Forklift H3.50-5.50XM, H70-120XM, S3.50-120XM Service Manual

2005 Hyster S70XL-S120XLS (S3.50-S5.50XL) Forklift Repair Service Manual 2005

2010-2015 Hyster Forklift S25XL S30XL S35XL Service Manual

Hyster C203 Forklift Service Manual

Hyster Forklift F005 Service Manual

Hyster Forklift Manuals - H70XL, H80XL, H90XL, H100XL, H110XL Service Repair Workshop Manual 2002 Edition

Hyster G108 E45Z, E50Z, E55Z, E60Z, E65Z Forklift Service Manual

1970-1985 Hyster H60E, H70E, H80E, H100E, H110E Service Manual

1970-1988 Hyster Forklift Service Repair Manual - D002 S30E-S120E H60E-H110E

1988-1991 Hyster Forklift Service Repair Manual

1990-1999 Hyster G005 H3.50XL H4.00XL-5 H4.00XL-6 H4.50XL H5.00XL Lift Truck Service Repair Manual

1990-2005 Hyster Forklift Service Manuals for H3.50-5.50XM, H6.00-7.00XL, S3.50-5.50XM, S6.00-7.00XL, S135-155XL2

1990-2005 Hyster H135-155XL, H135-155XL2 & S135-155XL Forklift Service Repair Manual

2001-2005 Yamaha YZF-R6 Service Manual

2003-2008 Hyster Forklift E2.00-3.20XM / N30XMH / V30ZMD Service Manual

2005 Forklift Service Manual

2005 Hyster Forklift L177, H2.0FT, H2.5FT, H3.0FT, H3.5FT Parts Manual & Service Reference

2005 Hyster J1.60XMT-2.00XMT (J160) Parts Manual

2008 Hyster W40Z / W45Z / W50Z Service Manual

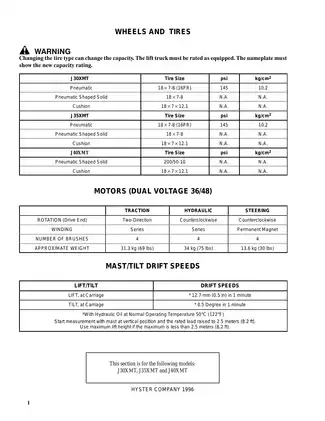

Forklift Hyster C160, J30XMT, J35XMT, J40XMT Service Manual

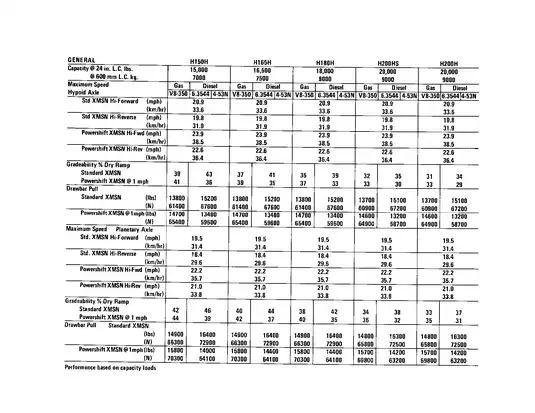

Forklift Hyster-Yale C007 H150H, H165H, H180H, H200HS, H200H, H225H, H250H, H275H, P150B, P200B Service Manual

Hyster A187, S40XL, S50XL, S60XL Forklift Service Manual 1995-2002

Hyster B177, H40XL, H50XL, H60XL Forklift Service Manual

Hyster F108, E45XM, E50XM, E55XM, E60XM, E65XM Forklift DC Motor Maintenance Manual

Hyster Forklift D001 H25XM, H30XM, H35XM, H40XMS Repair Manual

Hyster Forklift E004 S70XM S80XM S100XM S120XM S120XMS S80XMBCS S100XMBCS S3.50XM S4.00XM S4.50XM S5.50XM Service Manual

Hyster Forklift H007, H165XL, H190XL, H210XL, H230XL, H250XL, H280XL Service Manual

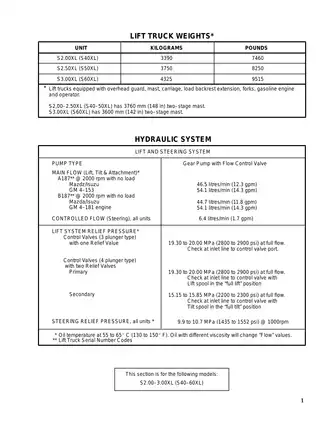

Hyster Forklift Service Manual for C108, E40XL, E50XL, E60XL Models

Hyster H2.00-H3.20XM Forklift (H177) Parts Manual

Hyster R30XM2 / R30XMA2 / R30XMF2 2260 SRM 138 Service Manual

Hyster S2.00-3.20XM S40-65XM H177 D187 / H2.00-3.20XM H40-65XM D177 / H2.00-3.20XM H45-65XM H177 Service Manual

![Hyster S3.50-5.50XM (S70-120XM) [E004, F004] Capacities and Specifications](/static/images/previews/ca8fa33/ca8fa33_preview-1.webp)