2003 Suzuki AN400 Burgman Service Manual

Complete service procedures for all systems: engine, transmission, electrical, cooling, braking, suspension and chassis maintenance with detailed torque specifications.

Manual Preview

Sample pages from the 2003 Suzuki AN400 Burgman Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki AN400 — 2003 Technical Service Documentation | AN400 Series Module.

- Calibrated Valve Gap Data: Intake clearance is measured at 0.08–0.13 mm when cold, establishing the precise valve timing Margin.

- Rated Spark Electrode Spacing: For optimal ignition, 0.7–0.8 mm defines the critical spark plug gap Protocol.

- Primary Idle Regulation: Engine speed maintains 1,400 ± 50 r/min during no-load operation, representing the baseline throttle-closed Architecture.

- Universal Engine Oil Volume: The engine capacity reaches 2,000 ml when replacing the filter along with routine oil maintenance Norms.

- Maximum Compression Specification: Nominal cylinder pressure is rated at 880 kPa (8.8 kgf/cm²) measured at 410 rpm during compression testing Bounds.

- Documented Coolant Capacity: The refrigerant system delivers 1,500 ml total fill volume for complete thermal management coverage Topology.

Professional Workshop Service Manual & Technical Specifications

Multi-System Operator's Manual: Maxi Scooter Comprehensive Suzuki AN400 Burgman Service Manual (2003) Maintenance & Repair Guide Knowledge-Base

Subsystem-Focus: Suzuki AN400 2003 // Model-Specs: Service reference logic and technical systems // Calibration-Scope: Complete procedural documentation.

| Document Section | Coverage | Reference Details |

|---|---|---|

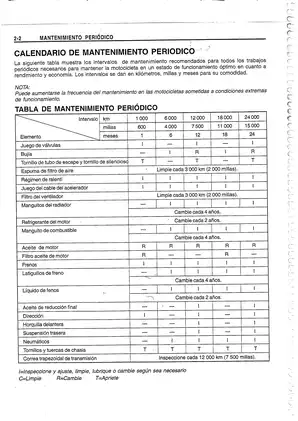

| Maintenance Schedules | Periodic service intervals and component management | Documented specifications provided |

| Engine Systems | Motor operation and component assembly | Complete specifications provided |

| Fuel and Lubrication | Carburetor and oil distribution networks | See Chapter 4 |

Diagnostic procedures address valve adjustment and engine compression testing, cooling system maintenance and refrigerant procedures, fuel carburetor operation and supply management, brake system fluid and component service, suspension and steering geometry inspection, electrical system charging and ignition diagnostics, and chassis component removal and reinstallation.

Integrated Threshold

Testing requirements are specified for valve clearance measurements and compression verification. The document includes detailed torque specifications for the cylinder head to ensure proper axial load stability. Clearance measurements are addressed for piston-to-cylinder tolerances and bearing journal dimensions. The manual provides inspection procedures for fuel system components including float height adjustment and carburetor level verification.

Strategic Interface

Special procedures are addressed for brake system bleeding and pad replacement methodology. Verification procedures are included for cooling system pressure testing and thermostat operation validation. The document covers continuous variable transmission belt inspection and clutch engagement point verification techniques. Repair information is provided for front fork disassembly, seal replacement, and oil level adjustment procedures.

Operational Benchmarks

The reference guides suspension damping adjustment protocols and brake lock mechanism calibration sequences. Electrical system diagnostics incorporate generator output measurement, ignition timing signal verification, and battery charging voltage confirmation. Wiring diagram documentation enables technician identification of component interconnections and circuit routing throughout the powertrain assembly.

Operational Parameters

The document references engine performance baseline measurements and operational tolerance windows for internal combustion systems. Technical data sections include detailed component dimensional specifications and wear limit thresholds for mechanical parts assessment. Procedural guides address transmission fluid service intervals and differential reduction gear maintenance requirements.

Strategic Benchmarks

System operation documentation covers automated choke enrichment functioning and diaphragm-controlled carburetor air velocity regulation. The manual documents mechanical linkage adjustment sequences for throttle cable tension and idle speed tuning. Chassis geometry and alignment specifications provide reference data for suspension articulation and steering head bearing assembly procedures.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Maxi Scooter manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)