2001-2002 Sea-Doo Utopia 185 / 205 Shop Manual (100 P.)

Service reference for Bombardier Utopia jet boats covering fuel systems, electrical, steering, and hull repairs. Includes technical data, wiring diagrams, and maintenance procedures. PN LMR2002-001.

Manual Preview

Sample pages from the 2001-2002 Sea-Doo Utopia 185 / 205 Shop Manual (100 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Bombardier Sea-Doo Utopia 185 & 205 — 2001–2002 Licensed Strategic Compendium | Utopia Series Volume.

- Engineered Dimensional Tolerance: Maximum overall length is calibrated to 5.56 m (18 ft 3 in) for the 185 model benchmark.

- Defined Output Rating: For optimal performance, 179 kW (240 HP) @ 6250 RPM establishes the peak engine power requirement range.

- Standard Working Temperature: The cooling system supports an open circuit direct water flow design baseline.

- Principal Component Weight: The 185 model requires 930 kg (2050 lb) dry weight in standard configuration sequences.

- Advanced Tension Specs: Steering nozzle pivoting angle is specified as 26° specification threshold.

- Verified Assembly Gap: Minimum required water level defines 90 cm (35 in) operational parameter standards.

Professional Workshop Service Manual & Technical Specifications

Integrated Troubleshooting Technical Manual: Jet Boat Sea-Doo Utopia 185 & 205 Sport Boats Repair & Maintenance Handbook 2001-2002 Factory Edition Workshop-Compendium

Engineering-Base: Utopia 185 (2001, 2002), Utopia 205 (2002) // Engine-Type: V-6 two-stroke propulsion systems with Mercury Marine technology // Engineering-Base: Factory service documentation for recreational sport boat platforms.

| Assessment-Element | Baseline | Calibration-Data |

|---|---|---|

| Document Pages | 98 | Complete specifications provided |

| Engine Options | 200 Opti, 210, 240 EFI | Torque specifications documented |

| Fuel System | Tank capacity 151L, pressurization procedures | 34 kPa test parameters included |

| Electrical Configuration | 12V CDI ignition, battery cut-off system | Fuse ratings and sensor data documented |

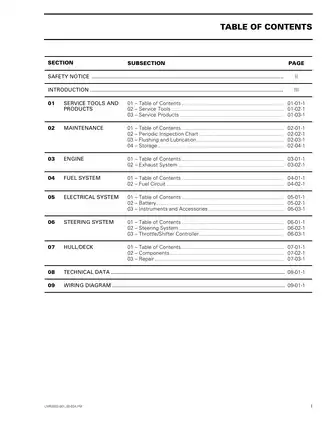

Systematizing the service groups into the maintenance chapter, the exhaustive system overview, the steering control mechanisms, the hull and fiberglass repair procedures, and the complete technical reference data, this manual assembles comprehensive factory documentation. The service manual covers foundational maintenance procedures including periodic inspection scheduling for fuel system integrity, lubrication protocols for throttle and steering cables, and seasonal storage procedures. Technical notes are provided for exhaust system components featuring dual muffler assemblies, hose inserts to prevent burn-through, and outlet configurations specific to engine variants. Quality checks are addressed for fuel tank pressurization at 34 kPa, sensor resistance verification using digital multimeter equipment, and vent valve ball movement validation.

The electrical system documentation includes battery installation parameters, post positioning toward stern orientation, maximum allowable dimensions of 267mm × 172mm × 238mm for batteries, charging procedures for fully discharged units, and hydrometer specific gravity readings between 1.265-1.280 for fully charged conditions. The troubleshooting chapter addresses weak or discharged battery symptoms with systematic cause-and-remedy correlations covering oxidized posts, loose connections, faulty charging systems, and battery replacement criteria. Cooling system maintenance is addressed in references to direct water flow circuits requiring minimum 90cm water level, with detailed guidance on fresh water flushing essential for neutralizing corrosive salt or chemical effects.

Steering system documentation encompasses cable replacement procedures, low-speed control system cable installation for both carburetor and fuel-injection engine models, adjustment techniques for proper engagement at rubber bumpers, and helm assembly replacement with spacer positioning. The hull and deck section provides comprehensive fiberglass repair methodology documenting air bubble remediation, blister treatment, minor gelcoat fracture restoration using putty techniques, and compound fracture lamination procedures. Repair procedures reference materials required including fiberglass mat and cloth, polyester resin, acetone cleaning solutions, and progressive grit sandpaper sequences from 100-grit through 1000-grit wet sanding applications. The document includes torque specifications for fastener assembly throughout engine, steering, electrical, and throttle controller subsystems to ensure proper structural integrity and secure component attachment.

Complete reference data encompasses engine specifications listing six-cylinder displacement, electric starting systems, fuel injection pump lubrication, induction through reed valve technology, and low-speed RPM adjustment to 1800 baseline. Capacity information documents fuel tank reserve totaling 151 liters, main injection oil reservoir volume of 11 liters, and load limits of 8 passengers or 600kg for calm water operation. Wiring diagram sections provide circuit identification, connector labeling with C-series and S-series designations, wire color coding with primary and tracer color schemes, and complete electrical harness routing for all systems. The manual documents detailed component locations for bilge pump and water bypass system outlets, drain tube routing specifications with siphoning prevention through hole perforation, and hull compartment bulkhead configuration for engine accessibility.

Specialized procedures address fuel system removal and installation requiring engine compartment wall panel cutout at specific dimensions, with foam sound wall retention and silicone seal application around cover penetrations. Carburetor and fuel pump diaphragm testing procedures employ pump gauge tester equipment pressurization to 28 kPa validation, with 10-second pressure retention confirmation for intact diaphragm integrity. The document includes detailed exploded view illustrations with numbered component identification, fastener torque values in both Newton-meters and pound-force feet notation, and Loctite application specifications by chemical formulation (243, 271, 425, 454 variants) for targeted fastener security and vibration resistance.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Jet Boat manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)