2008 Arctic Cat 366 ATV Service Manual

366 engine, transmission, fuel system, electrical & drive components. Full torque specs, 95-115 psi compression, 1250-1350 RPM idle, and all service procedures. PN: 0740-600

Manual Preview

Sample pages from the 2008 Arctic Cat 366 ATV Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Arctic Cat 366 — 2008 Technical Service Archive | 366 Series Repository.

- Consolidated Tank Capacity: 15.1 L (4.0 U.S. gal.) is established at the fuel storage specifications Architecture.

- Measured Engine Displacement: For optimal performance, 81.0 x 71.2 mm (3.19 x 2.80 in.) bore x stroke reaches maximum cylinder dimensions Protocol.

- Published Oil Capacity: 3.3 L (3.5 U.S. qt) during complete overhaul dictates the recommended fill volume Norms.

- Reference Tire Specification: The front tire requires 24 x 8-12 size, and rear tire standardized to 24 x 10-12 for proper clearance Framework.

- Fundamental Pressure Rating: Inflation pressure is standardized to 0.28 kg/cm² (4 psi) across both front and rear tires Bounds.

- Universal Valve Clearance: Intake valve gap reaches 0.076-0.127 mm (0.003-0.005 in.) as the critical adjustment specification Topology.

Professional Workshop Service Manual & Technical Specifications

In-Depth Performance Safety Manual: 2008 Arctic Cat 366 ATV Logic-Archive

Technical-Benchmarks: 366 / Arctic Cat // Technical-Domain: Engine and transmission systems / Drive system logic // Technical-Benchmarks: Service procedures and component specifications.

| Component | Baseline | Calibration-Spec |

|---|---|---|

| Engine/Transmission | 4-stroke, fuel-injected | Specifications documented across sections 1-3 |

| Drive System | Front/rear differentials, CVT clutch | Detailed procedures for inspection and service |

| Suspension | Double A-arm front/rear | Shock absorber and bushing documentation |

| Electrical System | 12V charging, CDI ignition | Component testing and troubleshooting guides |

| Brake System | Hydraulic disc brakes | Caliper and master cylinder service data |

Coverage is segmented into nine major sections addressing general information and specifications, periodic maintenance requirements, engine and transmission service procedures, fuel system components and carburetor adjustment, comprehensive electrical system documentation, drive system assembly and repair, suspension component servicing, steering and frame structure, and control systems including brake and throttle mechanisms that form the core technical reference for the 2008 model year.

Core Standard

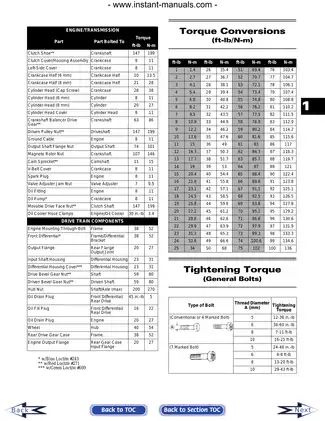

Accurately requiring a thorough examination of engine specifications, the document provides detailed torque values for crankshaft assembly, cylinder head fasteners, and transmission components. Technical specifications include piston skirt clearance ranges documented between 0.060-0.073 mm, valve/tappet clearance measurements for both intake and exhaust systems, and connecting rod dimensions with precise bearing specifications. The manual encompasses break-in procedure requirements, oil viscosity recommendations specifying Arctic Cat ACX All-Weather synthetic engine oil, and fuel grade specifications requiring 87 octane minimum regular unleaded gasoline.

Strategic Nexus

The drive system documentation covers front and rear differential construction, including gear case assembly procedures with backlash specifications between 0.28-0.38 mm and ring gear end play tolerance of 0.1-0.2 mm. Drive axle removal and installation includes detailed CV boot clamp positioning and bearing ring installation guidance. The rear gear case service section documents input shaft assembly procedures with seal installation requirements and secondary gear tooth contact verification methods. Propeller shaft coupling alignment and front drive actuator operation testing are thoroughly documented to establish proper power transmission routing.

Advanced Nexus

The electrical system module references 12-volt system architecture with battery specifications requiring DOT 4 brake fluid compatibility and charging output verification between 14-15.5 DC volts during engine operation. CDI ignition timing documentation specifies 10° BTDC at 1500 RPM with peak voltage measurements recorded between 250-375 DC volts across the primary ignition circuit. Starter relay function, ignition coil resistance testing, and spark plug gap adjustment to 0.7-0.8 mm are included for complete ignition system understanding. Fuse block identification and electrical component testing procedures using multimeter equipment provide diagnostic pathways for system troubleshooting.

Modular Parameters

Brake system documentation details hydraulic fluid specifications and caliper assembly procedures with pad wear thickness minimum of 1.0 mm before replacement becomes necessary. Master cylinder inspection includes fluid level verification through sight glass observation on the hand brake assembly. Brake hose routing and bleeder screw locations are specified for both front and rear hydraulic circuits. The document includes brake pad burnishing procedures and auxiliary brake pedal adjustment protocols to maintain braking performance standards. Hydraulic system pressure testing and fluid contamination prevention methods establish maintenance requirements for reliable brake operation.

Operational Threshold

Carburetor specifications document the Keihin CVK34 unit with main jet size 112, slow jet designation 35, and pilot screw initial setting of 2¾ turns from seated position. Float height reference data specifies 17 mm measurement when the carburetor is positioned on its side. Throttle cable free-play requirements are documented between 3-6 mm at the lever, with idle RPM target range of 1250-1350 during warm engine operation. Intake air silencer ducting and choke operation procedures support complete fuel delivery system documentation. Oil pressure specifications requiring 1.1-1.7 kg/cm² at 3000 RPM provide baseline verification data for lubrication system functionality.

The manual documents torque specifications for the fuel system components to ensure proper seal and leak prevention across all connection points throughout the engine bay.

Content Note: This manual provides comprehensive technical documentation for the 2008 Arctic Cat 366 ATV across nine operational sections, serving as the primary reference guide for authorized service technicians and experienced mechanics requiring detailed procedural and specification data.

FAQ

Customer Reviews

Read what our customers say about this Arctic Cat ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)