2008–2009 Suzuki DR-Z70 / DR-Z70K8 / DR-Z70K9 Service Manual

Addresses 67cc OHC engine systems including cylinder head, valve clearance, spark plug, fuel system with MIKUNI VM13SH carburetor, clutch inspection, drive chain adjustment, and brake maintenance procedures with detailed torque specifications.

Manual Preview

Sample pages from the 2008–2009 Suzuki DR-Z70 / DR-Z70K8 / DR-Z70K9 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki DR-Z70K8, DR-Z70K9 — 2008–2009 Analytical Engineering Archive | DR-Z70 Series Module.

- Maximum Addressable Resolution: 67 cm³ (4.1 cu.in) is measured at the engine displacement Architecture.

- Authorized Bolt Torques: For secure fastening, 23 N·m (2.3 kgf-m, 16.5 lb-ft) maintains the muffler mounting nut Topology.

- Established Tank Capacity: The fuel tank produces 3.0 L (0.8/0.7 US/Imp gal) including reserve Matrix.

- Measured Dimensional Tolerance: 0.04 – 0.07 mm (0.0016 – 0.0028 in) represents the intake valve clearance when cold Standards.

- Critical Climate Parameters: Engine idle speed limits to 1 600 ± 100 r/min at operating temperature Margin.

- Rated Imaging Specs: Maximum compression reaches 1 700 kPa (17 kgf/cm², 242 psi) at standard operation Protocol.

Professional Workshop Service Manual & Technical Specifications

Multi-System undefined Calibration Manual: Precision Repairs: Suzuki DR-Z70, DR-Z70K8 & DR-Z70K9 (2008–2009) Official Service & Maintenance Guide Manual-Nexus

Operational-Scope: SUZUKI DR-Z70K8 (2008), SUZUKI DR-Z70K9 (2009) // Performance-Values: Motorcycle maintenance and service / Multi-system operations Logic // Operational-Scope: Comprehensive repair documentation for dual-year models with complete technical specifications.

| System Component | Documentation Focus | Specifications |

|---|---|---|

| Engine & Drivetrain | Disassembly, inspection, and component servicing | Complete specifications provided |

| Chassis & Suspension | Assembly and alignment procedures | Documented |

| Electrical & Charging | Circuit function and testing methodology | Logic |

Integrated service sections encompass the General Information foundation covering model identification and fuel/oil recommendations, alongside Periodic Maintenance procedures addressing air cleaner maintenance, valve clearance adjustments, spark plug service, fuel system checks, engine oil changes, throttle cable inspection, idle speed tuning, clutch operation, drive chain care, brake adjustment, tire inspection, spoke nipple tightening, steering stem attention, front fork maintenance, rear suspension evaluation, and comprehensive chassis fastener verification. The Engine section then provides detailed procedures for cylinder head service including valve mechanism disassembly, rocker arm inspection, camshaft replacement, and valve spring removal, followed by cylinder bore measurement, piston ring clearance verification, conrod deflection analysis, crankshaft runout assessment, and comprehensive transmission component servicing involving gearshift fork inspection, gear ratio analysis, and clutch plate thickness evaluation.

Structured Interface

Steering component information is provided for understanding the Fuel System architecture, which encompasses fuel tank construction with breather hose routing, fuel valve operation, fuel hose integrity inspection, and carburetor assembly and disassembly procedures. The fuel section documents carburetor specifications including bore size, I.D. number location, float height adjustment, main jet and needle jet identification, pilot jet sizing, air screw settings, and throttle cable play measurement. Inspection guidelines are included for checking fuel filter condition, carburetor parts verification, needle valve function, pilot jet patency, and fuel overflow diagnosis.

Diagnostic Nexus

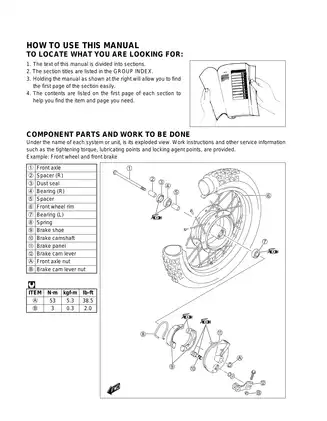

Alignment specifications are included for the Chassis section, which addresses both front and rear brake drum inspection with wear limit documentation, brake shoe examination, brake lever play adjustment, and rear brake pedal free travel verification. The front wheel assembly section documents brake camshaft maintenance, bearing installation procedures with grease application, and dust seal replacement protocols. Detailed front fork construction information covers spring free length measurement, stopper wear evaluation, and inner tube sliding surface inspection. The steering system provides bearing race installation methodology, steering stem nut adjustment, and handlebar position alignment.

Comprehensive Architecture

Reference data is included for the Electrical System, which documents the charging system with regulated voltage measurement at specified engine RPM, generator coil resistance testing, regulator/rectifier inspection using diode test methodology, and battery initial charging procedures with electrolyte filling instructions. The ignition system encompasses ignition coil primary peak voltage measurement, spark plug specification and gap documentation, pick-up coil peak voltage assessment, and pick-up coil resistance verification. Starter system documentation includes starter motor disassembly with brush length measurement, commutator inspection for discoloration and undercut, armature coil continuity testing, and carbon brush wear evaluation.

Systematic Sequences

This manual covers the Servicing Information sections containing comprehensive troubleshooting guidance organized by system, including engine complaint categories with symptom descriptions and remedy directions, clutch malfunction diagnosis, carburetor performance issues, chassis problem analysis, brake system defect identification, electrical circuit troubleshooting, and battery condition assessment. The document provides wiring diagram representation showing coupler locations, lead wire color designations, and circuit routing paths. Special tools inventory includes precision measurement instruments such as vernier calipers, micrometers, dial gauges, and specialty removal/installation equipment with part numbers for technician reference.

Advanced Methodology

The manual documents torque specifications for the front axle nut assembly stress control, ensuring proper fastening methodology across engine mounting nuts, exhaust pipe bolts, cylinder head nuts, camshaft sprocket bolts, transmission component fasteners, and all chassis assembly bolts and nuts with values presented in newton-meters, kilogram-force-meters, and pound-force-feet. Fuel system specifications detail the MIKUNI VM13SH carburetor configuration, NGK CR7HSA spark plug designation, battery type designation YT4B-BS with 12V capacity, engine oil SAE 10W-40 specification, tire pressure cold inflation documentation, and drive chain D.I.D 428 with 78-link configuration. Periodic maintenance schedule charts indicate inspection intervals, cleaning frequencies, replacement cycles, and tightening requirements for each motorcycle system component across initial startup, monthly, six-month, and annual service intervals.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)