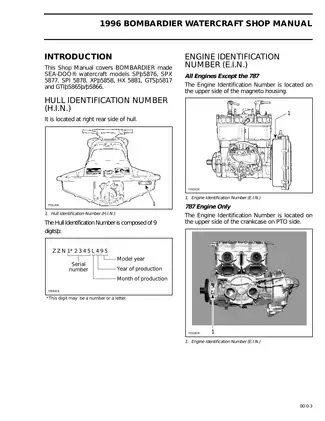

1996 Sea-Doo SP/SPI/SPX/XP/HX/GTS/GTI PWC Shop Manual

Technical reference for all 1996 Sea-Doo models including Rotax engine teardown, jet pump service, and electrical diagnostics. Complete OEM shop procedures with torque specs and part numbers.

Manual Preview

Sample pages from the 1996 Sea-Doo SP/SPI/SPX/XP/HX/GTS/GTI PWC Shop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Sea-Doo SP / SPI / SPX / XP / HX / GTS / GTI — 1996 Systematic Technical Dossier | PWC Engine Repository.

- Nominal Feed Speed: Idle speed is set to 1500 RPM when watercraft is in water, defining operational baseline Framework.

- Prescribed Size Parameters: For 587 engine, 1.2–1.8 mm (.047–.071 in) squish gap corresponds to combustion chamber clearance Threshold.

- Calibrated Imaging Specs: Piston / cylinder wall clearance for 587 engine is 0.05–0.07 mm (.002–.0028 in), specifying bore tolerance Mapping.

- Documented Fluid Capacity: Jet pump oil reservoir dictates 90 mL (3.0 U.S. oz) capacity using synthetic 75W90 GL5 polyolester oil Configuration.

- Defined End Play: Maximum impeller shaft end play limits 0.12–0.54 mm (.005–.021 in) radial displacement Benchmarks.

- System Processing Speed: Engine rev limiter is standardized to 6550 ± 50 RPM for 587 engine, 7000 ± 50 RPM for 717 engine Range.

Professional Workshop Service Manual & Technical Specifications

Thorough Technical Manual: Personal Watercraft (PWC) Sea-Doo SP/SPI/SPX/XP/HX/GTS/GTI Standards-Vault

Model-Portfolio: Sea-Doo SP (5876), SPI (5878), SPX (5877), XP (5858/5859), HX (5881), GTS (5817), GTI (5865/5866) // Technical-Domain: Rotax 587/717/787 Engine Logic, Bombardier Formula Pump Propulsion, CDI/DC-CDI Ignition Systems // Subsystem-Focus: Multi-engine service specifications, jet pump architecture, RAVE exhaust valve function documentation.

| Documentation Section | Coverage Category | Reference Material |

|---|---|---|

| Engine Systems | Rotax 587, 717, 787 platform configurations with top/bottom-end assemblies | Complete specifications provided |

| Propulsion & Drive | Jet pump disassembly, impeller wear ring clearance, drive shaft alignment, reverse system procedures | See Chapters 09-01 through 09-04 |

| Electrical & Controls | Magneto, CDI/DC-CDI ignition, charging system, DESS security module, variable trim system | Documented specifications included |

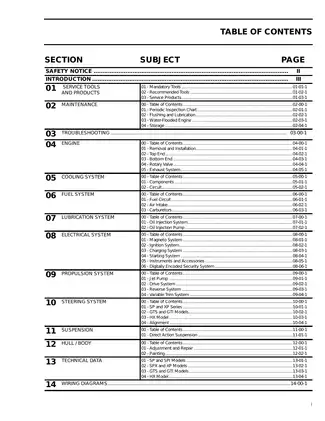

Systematizing the service groups into Engine (top/bottom-end, rotary valve, exhaust), Cooling System (Serial Cooling, water injection, elbow fittings), Fuel System (carburetors, oil injection pump synchronization), Electrical (magneto systems, ignition timing, starting motor), Propulsion (jet pump, drive system, reverse mechanism), and Steering (handlebar assembly, trim systems), the manual provides comprehensive technical information across seven primary powerplant configurations and seven distinct watercraft models.

Strategic Nexus

Engine rebuild procedures are documented for the 587 and 717 engines featuring Rotax Capacitor Discharge Ignition systems with integrated multi-purpose electronic modules, while the 787 engine incorporates a digital DC-CDI system with separate rear electrical box mounting and RAVE (Rotax Adjustable Variable Exhaust) automatic valve control. Logical system documentation includes crankshaft deflection measurement procedures, piston-to-cylinder wall clearance verification, squish gap establishment using solder methodology, and rotary valve timing specifications with opening/closing angle references for each engine platform. The manual documents torque specifications for critical fasteners to ensure proper gasket seal integrity throughout engine assembly and reassembly operations.

Structured Benchmarks

Drivetrain specifications are addressed in propulsion chapters detailing jet pump component inspection, impeller/wear ring clearance limits (maximum 1.0 mm), needle bearing radial play tolerance (0.05 mm maximum), and drive shaft deflection measurement techniques using V-block support. Service sections cover Bombardier Formula Pump architecture with single-stage axial flow design, crown spline transmission configuration, and nozzle angle adjustment parameters. The document includes reference data for impeller identification by pitch angle (ranging from fixed 18.8° to progressive pitch configurations), bearing installation methodology using specialized installer tools, and seal positioning requirements with lip orientation specifications.

Structured Interface

Reassembly procedures are specified for fuel system pressurization testing at 34 kPa (5 PSI) sustained pressure, oil injection system pressure testing at 21 kPa (3 PSI), and jet pump housing pressurization verification at 70 kPa (10 PSI) maximum. System documentation encompasses diaphragm carburetor specifications for Mikuni BN-38/BN-40I models with integrated fuel pump verification, needle valve pop-off pressure ranges varying by watercraft model (21-56 PSI), and low-speed screw adjustment sequences. The manual provides cooling system flushing procedures, antifreeze solution specifications for seasonal winterization, and water injection elbow fitting calibration data with stamped identification numbers and inlet/outlet diameter measurements.

Diagnostic Protocol

Service intervals are documented for periodic inspection at 10-hour, 25-hour, 50-hour, and 100-hour service cycles, with component-specific maintenance frequencies including spark plug replacement, carburetor adjustment, fuel filter/oil filter inspection, steering system verification, and variable trim system functional testing. Troubleshooting guidance addresses engine starting failure scenarios, misfiring conditions, performance loss at higher RPM ranges, and abnormal noise origination from propulsion systems. The document includes diagnostic procedures for ignition timing verification using stroboscopic timing lights, static test procedures with degree wheel positioning, and dynamic test methodology at specific RPM thresholds (6000 RPM for 587/717 engines, 3500 RPM for 787 engine).

Systematic Framework

Component locations are identified for magneto housing access, armature plate positioning, engine support mount configuration with shim documentation, battery removal sequence by cable polarity order, and jet pump support mounting on hull structures. The manual provides detailed wiring diagram references organized by section number, electrical connector color-coding documentation for MPEM and ignition system circuits, and safety lanyard switch verification procedures for DESS anti-theft system functionality. System descriptions include reverse gate spring tensioning, variable trim motor worm gear engagement, steering stem arm keyway alignment, and handlebar assembly installation with integrated throttle cable routing through bilge support structure.

Specialized service information documents carburetor synchronization for twin-carburetor engine configurations, impeller removal using heat application (150°C target) with Loctite bond breaking methodology, wear ring installation using arbor press force or hammer-strike progression technique, and bearing/seal installer tool operation to achieve precision depth positioning within lubrication reservoir zones. Reference sections detail oil injection system operation with variable-rate pump flow curves, battery hydrometer testing for specific gravity measurement, and charging system current output specifications ranging from 4 amperes (587/717) to 5 amperes (787) at 5500 RPM engine speed.

FAQ

Customer Reviews

Read what our customers say about this Sea-Doo Personal Watercraft (PWC) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)