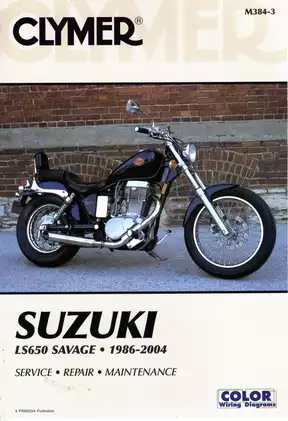

1986-2004 Suzuki LS650 Savage Service Manual

Complete service and repair documentation for Suzuki LS650 Savage addressing engine, clutch, transmission, fuel systems, suspension, and braking with detailed procedures and specifications.

Manual Preview

Sample pages from the 1986-2004 Suzuki LS650 Savage Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki LS650 Savage — 1986–2004 Systematic Resource Documentation | LS650 Series Repository.

- Published Climate Specs: Engine displacement reaches 652 cc (39.8 cu in) for the cylinder volume Bounds.

- Measured Heat Dissipation: Compression ratio is established at 8.5 to 1 for standard combustion efficiency Topology.

- Approved Linear Velocity: Standard compression pressure dictates 1,000–1,400 kPa (145–203 psi) at peak operating Matrix.

- Reference Scan Resolution: For optimal cold starting, spark plug gap corresponds to 0.8–0.9 mm (0.031–0.035 in.) Standards.

- Fundamental Liquid Volume: Cylinder bore and stroke yield 94.0 x 94.0 mm (3.70 x 3.70 in.) dimensions Margin.

- Universal Generation Capacity: Idle speed is set to 1,000–1,200 rpm for reliable engine operation Protocol.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Performance Hydraulic Manual: Suzuki LS650 Savage (1986-2004) Technical-Guide

Serial-Range: LS650 Savage (1986-2004) // Diagnostic-Area: Motorcycle Service & Maintenance Logic // Diagnostic-Area: Complete Engine, Transmission, and Systems Coverage.

| Assessment-Element | Parameters | Validation-Data |

|---|---|---|

| Document Structure | Twelve comprehensive chapters plus supplement | Complete specifications provided |

| Primary Systems Covered | Engine, Clutch, Transmission, Fuel, Electrical, Suspension, Brakes, Body | All chapters included |

| Technical Content Type | Service procedures, specifications, diagrams, inspection criteria | Full technical documentation |

Technical content addresses the cylinder head cover and camshaft assembly, the clutch and transmission mechanisms, and the fuel system with carburetor operation details. The document also covers the troubleshooting chapter to diagnose engine performance issues, the suspension components including front and rear assemblies, and the brake system maintenance. Additionally, lubrication and tune-up procedures are documented throughout with periodic maintenance intervals, and the electrical system section provides information on the charging system and starting components.

Structured Logic-Path

Quality checks are addressed for all major engine components, including measurement procedures for camshaft bearing journals, piston pin bore dimensions, and crankshaft runout specifications. The framework encompasses rocker arm inspection, valve guide clearance verification, and compression testing methodologies. The document provides reference data for torque specifications across engine mounting hardware, cylinder head fasteners, and lower-end assembly procedures. Practical guidance includes cylinder head cover bolt sequencing, camshaft timing alignment techniques, and crankcase sealant application methods to ensure proper oil containment and prevent leakage at critical sealing surfaces.

Comprehensive Benchmarks

The manual contains detailed examination criteria for piston rings, measuring groove width, end gap clearance, and side clearance in their installed positions within the cylinder bore. Technical information includes valve spring free length data, valve stem-to-guide clearance limits, and valve seat contact surface width specifications. Oil pump operational checks are documented, along with starter clutch directional rotation verification and gearing engagement assessment. The transmission section addresses shift fork-to-gear clearance measurement, internal shift mechanism inspection points, and synchronization of shift drum timing with external gearshift components.

Modular Nexus

The troubleshooting chapter documents engine starting conditions, performance malfunction analysis, and systematic diagnostic approaches for identifying fuel system obstructions, ignition system failures, and valve timing deviations. Carburetor service information includes float valve operation, pilot system fuel delivery, and main jet selection criteria for various engine loads. The exhaust system documentation covers pipe fitting tightness verification and gasket replacement protocols. Wiring diagrams and electrical connector identification reference the alternator stator configuration, neutral indicator switch function, and sidestand safety switch integration with the ignition system.

Comprehensive Threshold

Battery maintenance procedures are documented with hydrometer testing methodology for specific gravity measurement, electrolyte level adjustment using distilled water, and charging cycle duration guidelines. The front fork oil change process includes measurement techniques for proper oil level establishment using gauge tools or homemade measuring devices. Brake system procedures encompass disc brake fluid level inspection through viewing ports, brake line leakage detection, and brake pad wear assessment using wear groove indicators. The manual documents torque specifications for the crankshaft and connecting rod assembly, and references torque specifications for the primary drive gear nut to ensure proper structural alignment and secure fastening throughout the powertrain.

Modular Sequences

Control cable lubrication options are presented, comparing the oil method using paper cone apparatus with commercial cable lubricator tools for throttle and clutch cable maintenance. Drive belt inspection criteria include identification of broken teeth, missing teeth sections, cracked tooth damage, and uneven wear patterns on belt sides. Valve clearance adjustment procedures are documented for both intake and exhaust valves with feeler gauge technique guidance. Piston installation documentation includes arrow orientation verification relative to engine front positioning, pin clip gap orientation away from piston cutouts, and rocking motion verification along multiple axes.

Efficient technical guidance addresses the cylinder base gasket installation, piston ring end gap positioning staggered around the cylinder circumference, and camshaft chain tensioner preloding methodology using tie wrap restraint systems. The document provides reference material for compression pressure specification ranges, spark plug heat range selection criteria based on engine load conditions, and idle speed adjustment procedures using portable tachometer verification. Paint color spot identification on oil control rings indicates oversize designation standards, and balancer assembly spring-pin installation sequencing demonstrates proper synchronization with drive gear alignment marks.

Keywords by Category:

- Engines & Systems: Engine cooling, air-cooled four-stroke, single overhead camshaft, engine noises, vibration, compression testing, engine break-in

- Lubrication & Maintenance: Periodic lubrication, engine oil capacity, oil filter service, fork oil, grease specifications, cable lubrication methods

- Transmission & Clutch: 4-speed transmission, 5-speed transmission, gearshift mechanisms, shift fork clearance, clutch assembly, primary drive gear

- Fuel & Ignition: Fuel tank, carburetor adjustment, spark plug selection, ignition timing, automatic decompression cable, fuel shutoff valve

- Brake & Suspension: Disc brakes, drum brakes, front fork, rear suspension, drive belt tension, steering head bearings

- Specifications & Data: Torque specifications, valve clearance, tire pressure, battery state of charge, conversion formulas, tap and drill sizes

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)