1998 Mercury 25 BigFoot FourStroke Outboard Motor Service Manual

Mercury 25 BigFoot FourStroke outboard specifies valve lash and compression ratios. Service procedures cover carburetors, fuel systems, and powerhead assembly. PN 90-854785R2.

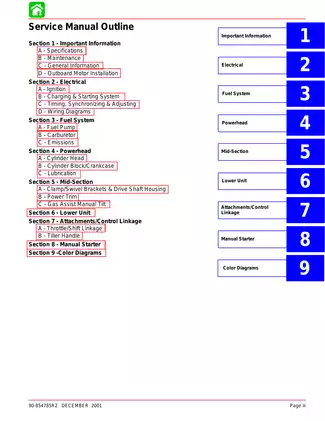

Manual Preview

Sample pages from the 1998 Mercury 25 BigFoot FourStroke Outboard Motor Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Mercury 25 BigFoot FourStroke (90-854785R2) — 1998–2001

Comprehensive Technical Handbook | 25 BigFoot Series Dossier.

-

Verified Cooling Specs: The thermostat valve begins opening at 136°F–143°F (58°C–62°C) and achieves full open position at 158°F (70°C), establishing the maximum water temperature margin Protocol.

-

Key Throughput Data: For optimal performance, 25 horsepower at 5750 RPM dictates the engine's maximum rated power output architecture.

-

Prescribed Dimensional Limits: The cylinder bore diameter corresponds to 2.5591 inches (65.0 mm) for standard specifications, with 0.003 inch (0.08 mm) taper/out-of-round maximum norms.

-

Nominal Torque Data: At 3000 RPM warm engine operation, 30–40 PSI yields the oil pressure specification threshold.

-

Design Containment Volume: Tank volume reaches 825 ± 25 RPM (out of gear) idle speed parameters.

-

Designated Environmental Range: Valve clearance is set to 0.006–0.010 inch (0.15–0.25 mm) intake and 0.010–0.014 inch (0.25–0.35 mm) exhaust topology.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Shop Manual: Mercury 25 BigFoot Outboard - Comprehensive Service & Repair Manual Troubleshooting-Index

Specification-Class: 25hp FourStroke / Mercury (Brunswick Corporation) // Model-Designation: 1998-current production, serial 0G590000–0T408999 / Four-stroke overhead camshaft logic // Specification-Class: 480 total pages, complete technical coverage, premium documentation.

| Category | Content | Documentation Status |

|---|---|---|

| Engine Systems | Cylinder head, block/crankcase, lubrication, ignition timing | Comprehensive specifications provided |

| Fuel & Emissions | Pump assembly, carburetor adjustment, EPA certification data | Complete specifications provided |

| Electrical Components | Stator, alternator, CDI ignition, charging/starting systems | See Chapter 2 (Electrical) |

Maintenance information covers powerhead lubrication, oil change procedures, spark plug inspection, fuel system maintenance, and cooling system flushing. The documentation addresses cylinder head and cylinder block procedures, including piston ring installation, connecting rod bearing clearance, and crankshaft measurement. Testing requirements are specified for compression checks, leakage testing analysis, and thermostat operation validation. Special procedures are addressed for water pump impeller replacement, gear housing service, and trim system disassembly. Diagnostic procedures accommodate ignition system troubleshooting, battery charging verification, and starter motor functionality assessment.

Operational Interface

The mid-section discusses power trim system operation, including trim "up," trim "down," maximum tilt, shock function, and manual tilt modes with corresponding hydraulic flow diagrams. Clamp bracket assemblies, swivel bracket configurations, and driveshaft housing mounting sequences receive detailed treatment. The lower unit documentation encompasses gear housing disassembly, bearing inspection, propeller shaft reconstruction, water pump seal replacement, and bearing carrier service. Control linkage sections cover shift cable adjustment procedures, throttle cable routing, and tiller handle assembly configuration.

Precise Nexus

Logical alignment between design intent and service execution characterizes the manual's approach to technical systems. Fuel system coverage includes pump operation, carburetor float level adjustment, and auto enrichener inspection. Maintenance schedules establish 100-hour and 300-hour service intervals, with special procedures for pre-storage preparation and fresh-water submersion recovery. Wiring diagrams (Section 2D) document electrical routing for electric start models, power trim relay configuration, and battery cable connections. The document includes color wiring schematics for power trim models, tiller handle configurations, and electric starter variants.

Diagnostic Interface

The manual documents torque specifications for the powerhead fasteners to ensure proper assembly. Exploded parts diagrams identify individual components for the flywheel assembly, electrical components, fuel pump, intake manifold, and complete lower unit gear housing. Service procedures address valve clearance adjustment (0.006–0.010 in. intake, 0.010–0.014 in. exhaust), timing belt inspection, and rocker arm shaft installation. Bearing carrier inspection protocols, propeller shaft disassembly sequences, and trim tab adjustment procedures receive systematic documentation.

Strategic Nexus

Powerhead installation sections integrate cylinder head torque sequences (staged two-step tightening), crankcase cover fastener patterns, and exhaust cover bolt applications. Charging system troubleshooting references alternator output curves, voltage regulator diode testing, and battery charging resistance measurement. Starting system documentation includes starter solenoid testing, starter motor disassembly/reassembly, and brush replacement procedures. The manual documents torque specifications for the mid-section pivot pins and power trim anchor fasteners to ensure secure assembly alignment.

Systematic Parameters

The manual provides complete specifications for all major systems: ignition timing (10° BTDC at idle for standard ECM units, advancing to 30° BTDC fully advanced), fuel pump pressure (3–6 PSI), and engine oil pressure (30–40 PSI at 3000 RPM warm engine). Piston ring specifications detail end gap clearances (top 0.006–0.012 in., middle 0.012–0.020 in., oil ring 0.008–0.028 in.) and side clearance tolerances. Valve seat width reconditioning uses 60°/45°/15° cutter angles, with seat width specification 0.035–0.043 in. Compression ratio reference data (9.8:1) and cylinder compression specification (180–210 psi peak) support engine diagnostics. The document includes propeller selection guidance, gear housing pressure test procedures, and water pump sealing methodology for both fresh-water and salt-water operation environments.

FAQ

Customer Reviews

Read what our customers say about this Mercury Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)