1999 Mercury / Mariner 40, 45, 50 (50 Bigfoot) Service Manual

Complete factory service guide for 1999 Mercury/Mariner 40-50 HP four-stroke outboards — powerhead, fuel, electrical, and trim/tilt systems. 610 pages of diagnostics, repair procedures, and parts specifications.

Manual Preview

Sample pages from the 1999 Mercury / Mariner 40, 45, 50 (50 Bigfoot) Service Manual manual

Purchase & Download

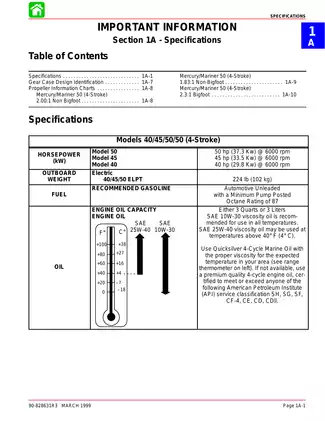

Models Covered & Key Technical Specifications

Mercury/Mariner 40, 45, 50 (50 Bigfoot) 4-Stroke Outboard — 1999 Structured Technical Repository | Outboard Engine Series Library.

- Documented Print Rate Data: 50 hp (37.3 kW) at 6000 rpm is calibrated to the maximum power output Benchmarks.

- Measured Dimensional Limits: For operational specifications, 57 cu. in. (935 cc) displacement is designed for four-cylinder architecture Range.

- Technical DPI Rating: Spark plug gap of 0.035 in. (1.0 mm) provides the standard ignition specification Sequences.

- Maximum Volume Data: Engine oil capacity reaches 3 quarts or 3 liters to maintain proper lubrication Baseline.

- System Running Clearance: Piston to cylinder clearance of 0.0014–0.0026 in. (0.035–0.065 mm) governs precision fit tolerances Requirements.

- Prescribed RPM Specs: Idle speed in forward gear establishes 725 ± 25 rpm (40/50 hp models) to determine stable engine operation Threshold.

Professional Workshop Service Manual & Technical Specifications

Systematic Training Manual: Mercury/Mariner 40, 45, 50 (50 Bigfoot) Outboard Service Manual - Complete Diagnostics & Repair Guide Blueprint-Vault

Engine-Type: Mercury/Mariner 40, 45, 50, 50 Bigfoot (1999 4-Stroke) // Architecture-Focus: Integrated Standard / Electrical & Hydraulic Systems Logic // Engine-Type: Complete service documentation with specification tables and diagnostic procedures.

| Section | Subsystem | Documentation |

|---|---|---|

| Electrical Systems | Ignition, charging, starting, trim/tilt circuits | Complete wiring diagrams, DVA voltage testing procedures, component specifications |

| Fuel Management | Carburetor tuning, pump operation, emission controls | Carburetor synchronization procedures, jet sizing reference, fuel system component identification |

| Powerhead Assembly | Cylinder head, block, crankcase, lubrication | Valve clearance specifications, torque sequencing, bearing clearance measurement methods |

Table of Contents Organization: Efficiently requiring thorough system understanding, the documentation covers specifications and maintenance schedules, electrical components including ignition and charging systems, fuel system carburetor adjustments and synchronization data, powerhead cylinder head and block procedures, mid-section trim/tilt hydraulic circuits with flow diagrams, and gear housing information. Structured around seven major sections spanning 610 pages of technical reference material in linear flow.

Structured Nexus

System operation descriptions cover ignition timing (5° to 35° BTDC), CDI capacitor discharge operation, stator assembly function, and trigger coil voltage generation. The documentation addresses alternator output specifications (12 volts, 10 amps regulated), starter motor designs for both top-mounted and side-mounted configurations, and battery requirements ranging from 465 to 1000 marine cranking amps depending on operating temperature. Assembly instructions are detailed for carburetor linkage components, intake manifold configuration, float height measurement (0.39 ± 0.02 inches), and pilot/main jet sizing for 40/45/50 horsepower models.

Structured Nexus

Hydraulic schematics are included for power trim systems covering trim-up, tilt-up, maximum tilt, trim-down, shock function up/return, and manual release modes with pressure relief specifications documented between 250–2800 psi depending on operation mode and horsepower rating. Steering component information is provided for swivel bracket assembly, transom mounting, drive shaft housing configuration, and control linkage adjustment procedures. The manual documents torque specifications for the connecting rod bolts (150 lb-in. at final step), crankshaft main bearing clearance (0.0005–0.0017 inches), and piston-to-cylinder clearance (0.0014–0.0026 inches) to ensure proper assembly alignment.

Integrated Standard

Valve clearance reference data is included for intake valves (0.006–0.010 inches cold) and exhaust valves (0.010–0.014 inches cold), with corresponding adjustment procedures using rocker arm assembly points #1–#4 in two-rotation sequences. Compression specification tables show 170–190 lb/in² peak readings for cold engine wide-open-throttle conditions, with cylinder leakage testing analysis using Snap-On MT324 equipment and interpretation guidance for identifying intake valve, exhaust valve, piston ring, or head gasket failure modes. Oil pump clearance specifications (outer rotor 0.001–0.006 inches, inner rotor 0.005 inches) establish dimensional limits for trochoid pump function verification.

Comprehensive Logic-Path

Electrical troubleshooting flow charts address no-spark conditions (both cylinders), weak spark scenarios, timing fluctuation, hard starting in cold/hot conditions, and rpm-limiting problems, with systematic test sequences using DVA (Direct Voltage Adapter) methodology at 400 VDC minimum. Power trim hydraulic troubleshooting diagrams guide technicians through outboard-will-not-hold-tilted-position scenarios, identifying manual release valve degradation, shock piston debris accumulation, check valve assembly damage, and suction seat blockage as probable causes. Starting circuit flow charts incorporate neutral start switch verification, fuse condition assessment (20-amp SFE rating), battery voltage confirmation (12 volts minimum), and starter solenoid functionality testing with step-by-step test point locations numbered 1–8.

Advanced Threshold

Specifications data includes cylinder bore dimensions (2.4803–2.4809 inches standard, 2.5003–2.5009 inches oversize 0.020"), piston ring end gap clearance (top ring 0.006–0.012 inches, second ring 0.012–0.020 inches, oil ring 0.008–0.028 inches), and crankshaft runout limit (0.0012 inches maximum). Carburetor specifications document idle rpm ranges (825–950 rpm out-of-gear depending on horsepower), wide-open-throttle targets (5500–6000 rpm), main jet sizing (#104 for 40/45hp carburetors #1–#2, #103 for carburetors #3–#4, #112 for 50hp models), and pilot jet reference (#42 standard). Thermostat data specifies valve opening temperature (136–143° F), full-open temperature (158° F), and valve lift (0.12 inches minimum), with corresponding maintenance check procedures and seasonal adjustment guidance for cold-start enrichment circuit operation.

FAQ

Customer Reviews

Read what our customers say about this Mercury Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)