Mercury 225 FourStroke EFI Service Manual 2003 Onwards

Complete powerhead diagnostics, fuel injection service, and electronic control system repair for Mercury's 225 hp 4-stroke outboard engine family starting 2003.

Manual Preview

Sample pages from the Mercury 225 FourStroke EFI Service Manual 2003 Onwards manual

Purchase & Download

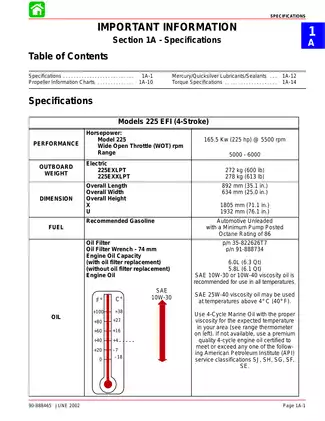

Models Covered & Key Technical Specifications

Mercury 225 FourStroke EFI — 2003 onwards Reference Engineering Manual | 225 EFI Series Collection.

- Prescribed Horsepower Specification: 165.5 kW (225 hp) is set to maximum rated output @ 5500 rpm engine speed Sequences.

- Nominal Fuel Capacity Specification: For optimal fuel management, 6.0 L (6.3 Qt) with oil filter replacement specifies the engine oil capacity Baseline.

- Calibrated Gap Specs: Spark plug electrode gap is set to 1.0–1.1 mm (0.39–0.43 in.) cold engine adjustment Requirements.

- System Displacement Data: 3352 cc (205 cid) — yields the six-cylinder four-stroke engine architecture Threshold.

- Technical Compression Ratio: The engine design requires 9.9:1 compression for standard combustion chamber ignition Mapping.

- Defined Idle Speed Rating: Idle speed in neutral produces 650–750 rpm nominal engine operation Configuration.

Professional Workshop Service Manual & Technical Specifications

Professional Installation Manual: Outboard Motor Essential Maintenance: Mercury 225 FourStroke EFI (2003 Onwards) Reference-Archive

Technical-Domain: Mercury 225 FourStroke EFI (2003 onwards) // Technical-Benchmarks: V6 DOHC 24-valve electronic fuel injection system / Microcomputer-controlled CDI ignition // Technical-Domain: 651-page service documentation with complete powerhead, electrical, and fuel systems coverage.

| System Category | Documentation Coverage | Reference Materials |

|---|---|---|

| Fuel Injection & Ignition | Complete EFI theory, diagnostics, service procedures, emissions standards | Specifications and adjustment procedures included |

| Electrical Systems | Charging system, starting system, timing control, sensor operations | Test procedures and component specifications documented |

| Powerhead Assembly | Cylinder head, crankcase, valve clearance, piston rings, bearing clearances | Complete disassembly/reassembly sequences with torque specifications |

Major sections focus on the powerhead architecture, providing the electrical and fuel injection systems documentation, covering comprehensive maintenance scheduling and diagnostic protocols, encompassing mid-section trim systems and lower unit assembly procedures, and detailing specifications for ignition timing, compression ratios, and valve clearances.

Structured Benchmarks

Special procedures are addressed for valve clearance adjustment and compression testing. This manual provides references for ignition timing windows, fuel pressure verification, and cylinder leakage analysis across all operating conditions. Complete network of torque specifications ensures proper fastener assembly throughout the powerhead and accessory systems.

Core Nexus

Verification procedures are included for stator coil output, crank position sensor signals, and throttle position calibration. The document includes comprehensive wiring diagrams for charging and starting circuits, along with detailed schematics for the electronic fuel injection system. Battery capacity recommendations and electrical component replacement specifications are cross-referenced with torque values.

Modular Methodology

Repair information is provided for fuel system components including the vapor separator, high-pressure fuel pump relay, and secondary vapor separator tank assembly. Service procedures document low-pressure fuel pump operation cycles, pressure regulator maintenance, and fuel injector cleaning protocols. Coolant routing and thermostat specifications support preventive maintenance on the water-cooled electrical system.

Systematic Nexus

The document includes coverage of idle air control motor operation, manifold absolute pressure sensor function, and intake air temperature monitoring. Detailed procedures address fuel filter element replacement, fuel cooler water passage maintenance, and vapor lock prevention through secondary separator operation. Diagnostic code information enables systematic identification of electronic control module failures.

Precise Architecture

Brake system specifications are included for power trim and tilt hydraulic pressure validation. The manual documents torque specifications for the cylinder head assembly to ensure proper gasket seal integrity. Complete lubrication point identification and grade specifications support ongoing maintenance across all engine bearings and critical surfaces.

FAQ

Customer Reviews

Read what our customers say about this Mercury Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)