2001-Newer Mercury 50/60 4-Stroke Outboard Service Manual

Mercury 50 & 60 4-Stroke outboard technical guide covering ignition systems, fuel delivery, powerhead assembly, and complete lower unit service procedures with pinion gear backlash specifications.

Manual Preview

Sample pages from the 2001-Newer Mercury 50/60 4-Stroke Outboard Service Manual manual

Purchase & Download

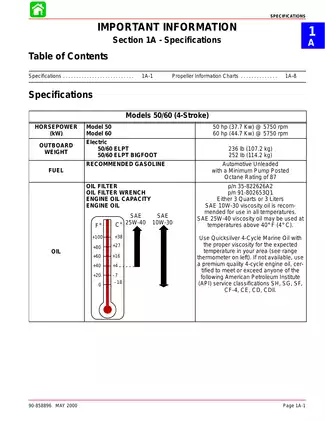

Models Covered & Key Technical Specifications

Mercury 50/60 4-Stroke Outboard Motor — 2001 and Newer Detailed Technical Specification | Outboard Motors Service Catalog.

- Authorized Horsepower Output: 50 hp (37.7 kW) and 60 hp (44.7 kW) at 5750 rpm represents the rated maximum power configuration Specifications.

- Calibrated Displacement Volume: 60.8 cubic inches (996 cc) is configured as the four-stroke engine cylinder displacement Requirements.

- Critical Engine Idle Speed: For optimal operation, 725 ± 25 rpm in forward gear defines the specified engine idle setting Threshold.

- Operational Oil Capacity: The engine sump maintains either 3 quarts or 3 liters as the total engine oil volume Mapping.

- Fundamental Gear Ratio Data: 1.83:1 is established at the gearcase for non-Bigfoot lower unit configuration Benchmarks.

- Maximum Gearcase Capacity: 11.5 fluid ounces (340 mL) requires the Quicksilver Gear Lube Premium Blend lubricant Range.

Professional Workshop Service Manual & Technical Specifications

Technical Calibration Wiring Manual: Outboard Motor 2001 and Newer Mercury 50 & 60 4-Stroke Outboard Motors - Comprehensive Service & Repair Guide OEM-Documentation

Asset-ID: Mercury 50 & 60 4-Stroke (2001 and newer) // Coverage-Scope: Electrical systems, fuel delivery, and powerhead assemblies / Comprehensive maintenance protocols // Asset-ID: Full-service documentation with OEM specifications and certified repair procedures.

| Assessment-Parameter | Baseline | Framework |

|---|---|---|

| Document Scope | 8 major sections | 563 pages of technical specifications |

| System Coverage | Electrical through lower unit components | Maintenance, assembly, and diagnostic procedures |

| Service Focus | Factory-certified repair methodology | Mercury Marine OEM standards |

Maintenance information covers engine ignition circuits and electrical system architecture, connecting battery charging components with starting mechanisms, detailing fuel system operation and carburetor adjustment protocols, and establishing powerhead assembly procedures alongside mid-section and lower unit service requirements.

Strategic Methodology

Fundamentally requiring systematic inspection protocols, this manual documents the electronic control module operation, stator assembly characteristics, and flywheel mechanics essential for engine function. The guide provides comprehensive coverage of capacitor discharge ignition systems, voltage regulation processes, and crank position sensor integration. Reference specifications for spark plug installation and ignition timing verification are included throughout.

Core Logic-Path

Fluid capacities are listed for engine lubrication and gear housing maintenance across multiple configurations. Tool requirements are listed for bearing removal, seal installation, and propeller shaft access. Installation guidelines are provided for crankcase covers, cylinder head assemblies, and manifold components supporting the fuel and cooling systems.

Systematic Benchmarks

Maintenance guidelines are included for routine valve clearance adjustment, oil change procedures, and seasonal storage preparation. Inspection protocols address thermostat function, compression testing methodology, and water pump impeller evaluation. The document includes wiring diagrams for electrical system troubleshooting, demonstrating complete diagnostic circuit pathways.

Core Parameters

OEM guidelines are included for bearing selection, piston ring gap measurement, and crankshaft runout assessment. Torque specifications are documented for critical fastener assembly ensuring proper mechanical integration. The manual provides reference data for connecting rod clearance verification, main bearing installation sequence, and power trim system hydraulic pressure settings.

The manual documents torque specifications for the cylinder head assembly to ensure proper component sealing and structural integrity. Comprehensive sections address emergency submersion recovery procedures, propeller selection methodology, and trim system operation under various load conditions. Full technical reference material supports both routine maintenance and major overhaul projects for Mercury 50 and 60 horsepower 4-stroke outboard motor systems manufactured from 2001 forward.

FAQ

Customer Reviews

Read what our customers say about this Mercury Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)