2001 Mercury 200 OptiMax Jet Drive Service Manual

Complete factory service documentation for Mercury 200 HP OptiMax Jet Drive covering direct fuel injection, powerhead rebuild, cooling system, and pump unit. Includes detailed specifications, torque charts, and repair procedures for 2001 model year engines starting serial number 0E384500.

Manual Preview

Sample pages from the 2001 Mercury 200 OptiMax Jet Drive Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Mercury 200 OptiMax Jet Drive (90-881986) — 2001 Expert Documentation Catalog | OptiMax Series Division.

- Calibrated Displacement Data: 153 cu. in. (2508 cc) is measured at the engine cylinder volume Architecture.

- Primary Power Output: For rated performance, 200 hp at 5150–5650 rpm establishes the maximum engine output Norms.

- System Pressure Data: Air compressor develops 110 psi pressure at wide open throttle limits the air system Bounds.

- Authorized Fuel Rail Specification: The fuel injectors require 89 ± 2 psi (613.5 ± 13.8 kPa) is set to achieve stoichiometric combustion Topology.

- Core Stroke Length: Engine displacement reaches 2.65 in. (67.3 mm) per piston travel Matrix.

- Standard Cooling Capacity: Drive housing oil reserve maintains 24 fl. oz. (710 ml) controls lubrication system Standards.

Professional Workshop Service Manual & Technical Specifications

Essential Operations Shop Manual: Mercury 200 HP OptiMax Jet Drive Service Manual - Comprehensive Repair Guide (2001) Factory-Standards

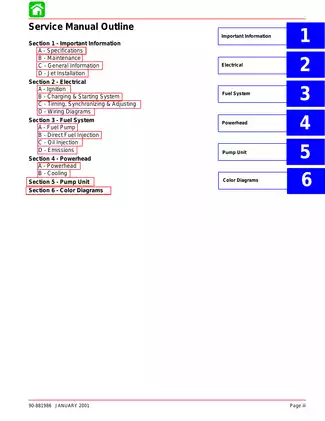

Diagnostic-Area: 200 OptiMax Jet Drive (2001) // Unit-Designations: Gasoline Engines / Direct Fuel Injection Logic // Diagnostic-Area: 371 pages, complete technical documentation, service procedures.

| Assessment-Element | Technical-Path | Framework |

|---|---|---|

| Ignition System Components | Spark plugs, coil drivers, ECM control | Complete specifications provided |

| Fuel Injection Architecture | Direct fuel injection, fuel rails, injectors | Chapter 3B documents systems |

| Engine Mechanical Systems | Crankshaft, pistons, connecting rods | See Chapter 4A |

| Jet Pump Operation | Impeller, stator, nozzle assembly | Section 5 details procedures |

| Electrical Configuration | Alternator, starter, charging system | Wiring diagrams included |

Reference chapters include powerhead and expansion chamber configurations, integrated service sections encompass ignition timing and throttle synchronization, comprehensive maintenance covers fuel system and oil injection protocols, technical framework addresses direct fuel injection operation and air compressor systems, and assembly instructions provide jet drive installation guidance.

Engineered Topology

Properly requiring careful attention to detail, the manual documents specifications for powerhead construction including cylinder block displacement of 153 cubic inches (2508 cc), V-6 configuration with 60-degree vee arrangement, and crankshaft maximum runout specifications. The document contains detailed information about piston diameter specifications, connecting rod assembly procedures, and bearing configurations essential for proper engine reconstruction.

Systematic Framework

Hydraulic schematics are included for jet pump drive housing components, water cooling passages throughout the powerhead, and air compressor lubrication circuits. The manual provides comprehensive reference data for the fuel injection system architecture, including fuel pressure specifications at 89 psi and air pressure at 79 psi, with tracker valve operation to maintain the differential between fuel and air systems. Direct injector specifications and fuel rail assembly information are documented with complete torque sequences.

Core Logic-Path

Steering component information is provided for rudder assembly, reverse gate positioning, and nozzle control mechanisms. The manual covers shift cable adjustment procedures, steering cable routing, and control linkage synchronization. Trim plate adjustment information addresses boat handling characteristics and porpoising prevention through mechanical trim system configuration.

Operational Standard

Inspection guidelines are provided for reed block condition assessment, impeller blade examination, and wear ring clearance verification. The document specifies cylinder bore specifications with standard diameter of 3.501 inches and oversize bore option of 3.516 inches. Piston ring end gap tolerances, spark plug gap settings at 0.040 inch, and thermostat temperature threshold of 142 degrees Fahrenheit are included as reference values.

Systematic Protocol

Alignment specifications are included for crankcase cover installation torque sequences, cylinder head bolt tightening procedures using progressive steps, and exhaust divider plate alignment. The manual documents the Direct Fuel Injection system framework with air plenum installation, vapor separator assembly, and fuel management assembly configuration. Water flow routing diagrams illustrate cooling passages from jet pump through powerhead, cylinder jackets, and expansion chamber circuits.

The service manual documents torque specifications for the impeller nut at 150 lb-ft to ensure proper gear engagement and crankshaft load distribution.

FAQ

Customer Reviews

Read what our customers say about this Mercury Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)