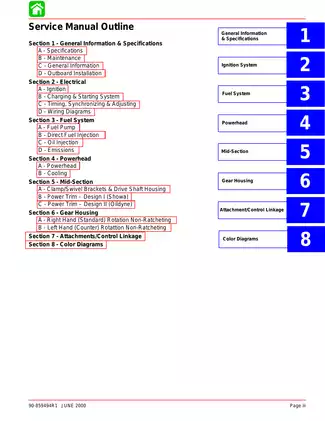

2000 Mercury Optimax 115 / 135 / 150 / 175 Service Manual

Covers Optimax models with detailed procedures for fuel delivery, ignition timing, and starting systems. Includes component part numbers and diagnostic guidance. Ref: 90-859494R1

Manual Preview

Sample pages from the 2000 Mercury Optimax 115 / 135 / 150 / 175 Service Manual manual

Purchase & Download

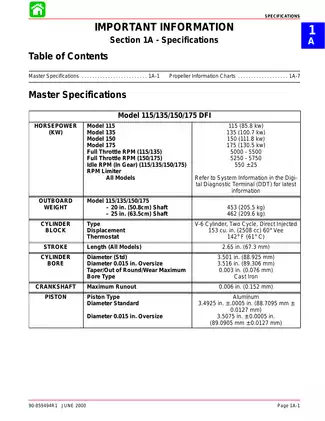

Models Covered & Key Technical Specifications

2000 Mercury Optimax 115 / 135 / 150 / 175 Service Manual: Mercury Outboard 2000 Optimax Service Manual Troubleshooting-Index 2000 Mercury Optimax 115 / 135 / 150 / 175 (90-859494R1) — 2000 Engineering & Technical Reference | Optimax Service Repository.

- Prescribed Cycle Rate: 5500 rpm maximum is specified as the upper throttle governor setting for the 115 and 135 horsepower configuration Bounds.

- Measured Rotation Data: For optimal engine performance, 5750 rpm is the rated high-speed limiting threshold for 150 and 175 horsepower models Topology.

- Core Installation Footprint: The air compressor displacement reaches 7.07 cu. in. (116 cc) with reciprocal piston rotation Matrix.

- Rated Threaded Fastener Data: The cylinder head assembly requires 30 lb-ft (41 Nm) initial torque then 90 degrees additional turn Standards.

- Technical Alignment Specs: Fuel pressure maintains 89 ± 2 psi (613.5 ± 13.8 kPa) against air pressure set to 79 ± 2 psi (544.0 ± 13.8 kPa) Margin.

- Advanced Output Performance: Maximum direct fuel injection discharge achieves 175 horsepower (130.5 kW) at stoichiometric 10 psi differential Protocol.

Professional Workshop Service Manual & Technical Specifications

Specialized Performance Shop Manual: Outboard Motor 2000 Mercury Optimax 115 / 135 / 150 / 175 Service Manual Troubleshooting-Index

Engine-Type: Mercury Optimax // Unit-Designations: 115/135/150/175 HP Outboard Engines // Engine-Type: Marine Direct Fuel Injection

Engine Performance Specifications

| Performance-Element | Operational-Logic | Calibration-Spec |

|---|---|---|

| Horsepower | 115 - 175 HP | N/A |

| Full Throttle RPM | 5000 - 5750 RPM | N/A |

| Idle RPM | 550 ± 25 RPM | N/A |

| Cylinder Bore | 3.501 in. (88.925 mm) | N/A |

| Stroke Length | 2.65 in. (67.3 mm) | N/A |

| Piston Diameter | 3.4925 in. ± .0005 in. | N/A |

Fundamentally requiring adherence to precise service intervals and specifications, this manual details the complete operational framework for Mercury Optimax outboard motors. It covers all essential systems, from ignition and fuel delivery to cooling and electrical components, ensuring optimal performance and longevity. Its structured approach facilitates efficient diagnostics and repairs, aligning with factory standards for engine maintenance.

System operation descriptions cover fuel delivery and air intake systems. This manual details the components within the fuel system, including the high and low pressure pumps, injectors, and associated regulators, ensuring a clear understanding of their function and maintenance requirements.

The documentation addresses the ignition system thoroughly, covering coils, coil drivers, crank position sensors, and throttle position sensors to guarantee accurate spark delivery and timing.

Assembly instructions are detailed for critical components such as the powerhead, mid-section, and gear housing, providing step-by-step guidance for correct installation and reassembly.

Hydraulic schematics are included for power trim and steering systems, crucial for maintaining control and maneuverability of the outboard.

Steering component information is provided for proper adjustment and maintenance, ensuring responsive and safe operation under various conditions.

This manual documents torque specifications for critical fasteners to ensure proper assembly and prevent fastener fatigue prevention. It provides comprehensive guidance for maintaining the integrity and performance of the Mercury Optimax engine.

FAQ

Customer Reviews

Read what our customers say about this Mercury Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)