1989-2002 Suzuki QuadRunner 160 / LT160E ATV Service Manual

Suzuki QuadRunner 160 LT160E troubleshooting and repair reference manual, covering models from 1989-2002. PN 99500–41112–01E.

Manual Preview

Sample pages from the 1989-2002 Suzuki QuadRunner 160 / LT160E ATV Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

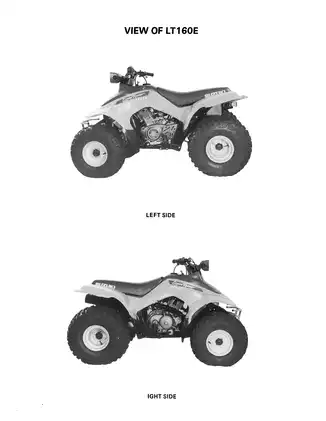

Suzuki LT160E / LT-F160 Series (PN 99500–41112–01E) — 1989–2002 This section describes service data, service specifications, and servicing procedures for the Suzuki LT160E / LT-F160 series.

- Reference Vault: For routine maintenance, 1200 rpm establishes the recommended idle speed.

- Technical Output Data: The engine requires 1500 ml for standard oil changes, defining the lubrication replenishment parameters.

- System Measurement Bounds: For optimal cooling, 158 cm³ defines the engine displacement.

- Defined Range: With a maximum of 9.2:1, the compression ratio is set to ensure efficient combustion.

- Nominal Resolution Data: 10° B.T.D.C. below 1000 r/min specifies the ignition timing at idle.

- Standard Package Size: The battery capacity is 12V 32.4 kC (9 Ah)/10 HR for reliable electrical power supply.

Professional Workshop Service Manual & Technical Specifications

Full-Coverage Calibration Manual: ATV Illustrated Suzuki LT160E / QuadRunner 160 repair manual: 1990-2002 PDF Documentation-Set

Assembly-Group: LT160E / LT-F160 Series (PN 99500–41112–01E) // Procedure-Type: ATV / All-Terrain Vehicle Logic // Engineering-Base: 1989–2002 service and repair.

The technical units are distributed across this manual to cover all aspects of the Suzuki QuadRunner 160 and LT160E models. From basic maintenance schedules to in-depth engine overhauls, this document serves as a complete reference.

| Specification | Value | Architecture |

|---|---|---|

| Engine Type | Four-stroke, air-cooled, OHC | Standard Configuration |

| Bore | 58.0 mm (2.283 in) | Engine Component |

| Stroke | 60.0 mm (2.362 in) | Engine Component |

| Displacement | 158 cm³ (9.6 cu in) | Engine Component |

| Transmission | Wet multi-plate, 5-speed constant mesh, 1-reverse | Drivetrain System |

| Ground Clearance | 135 mm (5.3 in) | Chassis Specification |

| Dry Mass | 152 kg (335 lbs) | Vehicle Weight |

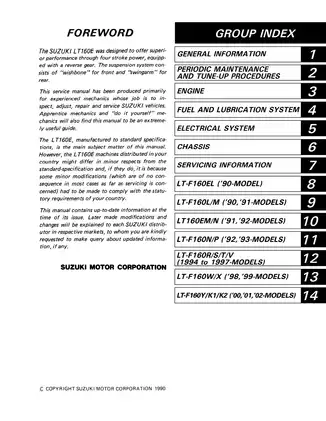

The "General Information" section provides an overview of the manual, VIN and serial number locations, and essential "Fuel and Oil Recommendations." "Periodic Maintenance and Tune-Up Procedures" details recommended service intervals for various components, including battery, engine nuts and bolts, valve clearance, and drive chain. The "Engine" section offers comprehensive coverage of engine components, removal and remounting, disassembly, and inspection. "Fuel and Lubrication System" covers the fuel cock, carburetor, and oil pressure. The "Electrical System" outlines the ignition, charging, and starter systems. "Chassis" details front and rear fenders, wheels, brakes, steering, suspension, and more. Finally, "Servicing Information" provides troubleshooting guides, wiring diagrams, and special tools. Appropriately demanding torque specifications for crucial components are documented to ensure proper clamp load consistency.

FAQ

Customer Reviews

Read what our customers say about this Suzuki ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)