1988-1992 Suzuki LT250R Service Manual

Documents water-cooled 246cc engine with crank balancer, exhaust valve control, and full-floating rear suspension. Complete periodic maintenance, tune-up, repair procedures, and chassis servicing.

Manual Preview

Sample pages from the 1988-1992 Suzuki LT250R Service Manual manual

Purchase & Download

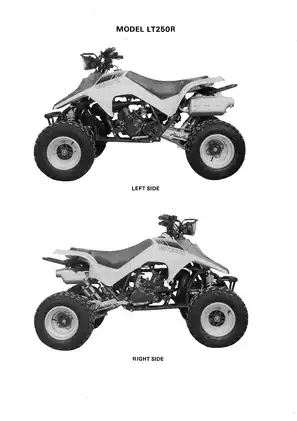

Models Covered & Key Technical Specifications

Suzuki LT250R — 1988–1992 Precision Technical Portfolio | LT250R Series Suite.

- Nominal Net Mass: The vehicle is configured at 147 kg (324 lb) total dry weight Benchmarks.

- Principal Scan Resolution: For cylinder performance, 67.0 mm (2.638 in) bore diameter limits the engine displacement requirements Range.

- Rated Rotational Force: 246 cm³ (15.0 cu in) — is set to the two-stroke piston displacement Sequences.

- Technical Play Limits: The compression chamber requires 8.0:1 for standard combustion pressure Baseline.

- Standard Temperature Range: Fuel tank capacity reaches 11.5 L (3.0 US gal) Parameters.

- Defined Enclosure Specs: Transmission oil volume is measured at 900 ml (30.4 US oz) Threshold.

Professional Workshop Service Manual & Technical Specifications

Advanced Assembly Manual: Suzuki LT250R ATV Specification-Set

Repair-Classification: LT250R, LT250RJ, LT250RK, LT250RL, LT250RM, LT250RN // Operational-Scope: Water-cooled two-stroke engine, full-floating rear suspension, and dual-disc braking systems / Complete technical subsystem documentation // Repair-Classification: Factory specifications, component service procedures, and maintenance interval tables included.

| Documentation Category | Content Coverage | Reference Material |

|---|---|---|

| Engine Systems | Water-cooled two-stroke with exhaust valve control, crankshaft assembly, transmission specifications | Complete specifications provided |

| Suspension & Steering | Double wishbone front suspension, full-floating rear suspension, steering geometry data | Documented with adjustment procedures |

| Brake Systems | Dual-disc hydraulic front and rear brakes, master cylinders, caliper assemblies | Service specifications included |

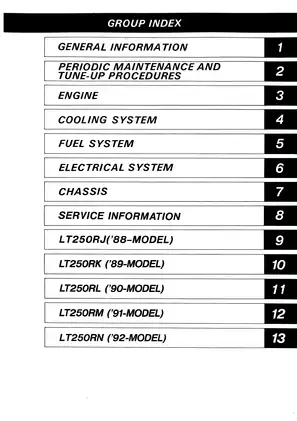

Reliably requiring systematic evaluation, the service manual comprehensively documents engine and transmission systems alongside complete cooling apparatus data. Factory specifications are documented for engine displacement (246 cm³), bore and stroke dimensions (67.0 × 70.0 mm), and compression ratio (8.0:1). The document covers engine removal and reinstallation procedures, clutch assembly configurations, gearshift mechanism operation, and transmission oil capacity specifications. Drivetrain specifications are addressed in detailed sections covering primary reduction ratio (2.681), gear ratios across six speeds, and final reduction ratio (3.500) with corresponding technical service parameters for all transmission components.

Technical Sequences

The manual includes comprehensive maintenance schedules outlining periodic service intervals for engine nuts and bolts tightening, spark plug replacement cycles, transmission oil changes, drive chain tension adjustment, coolant replacement requirements, and brake fluid servicing. Reassembly procedures are specified for crankshaft installation using specialized tools, piston ring positioning, cylinder head tightening sequences, and clutch plate assembly configurations. Engine component inspection protocols document bearing and oil seal serviceability criteria, piston-cylinder clearance limits, and conrod small end measurement procedures. Water pump disassembly and reassembly steps detail mechanical seal installation, impeller bolt torque application, and cooling system pressure testing requirements.

Integrated Methodology

Service intervals and documented specifications include carburetor settings with idle r/min adjustment data (1,400 ± 50 r/min.), main jet size (#240), needle jet configuration (Q-8), and float height specifications (11.9 ± 1.0 mm). Electrical system documentation covers ignition coil resistance ranges, magneto coil output specifications, spark plug gap requirements (0.55–0.65 mm), and lighting system voltage regulation data (13.0–14.0V at 5,000 r/min.). Fuel system procedures document carburetor cleaning protocols, fuel cock operation modes (OFF, RES, ON), float chamber assembly, and needle valve inspection criteria. Cooling solution mixing ratios (50:50 distilled water and anti-freeze) with alternative density adjustments for extreme temperature environments are included.

Strategic Parameters

Chassis documentation addresses front and rear wheel bearing inspection procedures, brake pad thickness measurement limits (1.0 mm service limit), disc runout inspection specifications (0.30 mm maximum), and tire pressure specifications with load capacity calculations. Steering system sections document toe-in adjustment procedures, steering geometry reference data (9° caster, 40 mm trail, 41° 30' steering angle), and shock absorber preload adjustment mechanisms. Rear axle assembly details include bearing installation sequences, dust seal application methods, sprocket flange serration greasing procedures, and wave washer positioning for lock nut installation. Documents torque specifications for frontend suspension components, with wishbone arm bolt torque ranges and steering shaft holder bolt specifications provided in comprehensive tabular format.

Advanced Logic-Path

The manual documents troubleshooting logic organized by system complaint, identifying probable causes and remedy sequences without prescriptive repair instructions. Engine troubleshooting covers compression diagnosis procedures, spark production assessment criteria, fuel delivery verification steps, and noise source differentiation methods. Carburetor troubleshooting documents starting difficulty indicators, idle/low-speed condition assessment, medium/high-speed operation analysis, and overflow detection parameters. Chassis troubleshooting sections address steering response characteristics, suspension firmness evaluation, brake performance assessment, and tire wear pattern diagnosis without specifying corrective action procedures. Electrical troubleshooting references ignition system component functionality testing, lighting circuit continuity inspection, and wiring diagram consultation protocols.

Modular Benchmarks

Service data tables document specifications across cylinder-piston-ring assemblies, conrod and crankshaft dimensions, exhaust valve opening/closing r/min. thresholds, clutch plate and spring measurements, transmission component ratios, drive chain specifications, and electrical system resistance values. Brake system documentation includes fluid pressure specifications for radiator cap valve release (110 ± 15 kPa), tire pressure specifications by load condition (0.20–0.30 kg/cm² front and rear), and chassis fastener tightening torque ranges from M4 through M18 bolt diameters. The document includes specialized tool part numbers for bearing removal/installation, crankcase separation, clutch assembly, piston pin extraction, and rotor installation procedures, with notation of tools unavailable in U.S. markets. Wiring diagrams reference lighting coil output specifications, CDI unit resistance measurement protocols, and magneto coil ohm-meter ranges requiring pocket tester equipment.

The service manual documents torque specifications for the engine, chassis fasteners, and brake system components to ensure proper assembly and operational safety.

FAQ

Customer Reviews

Read what our customers say about this Suzuki ATV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)